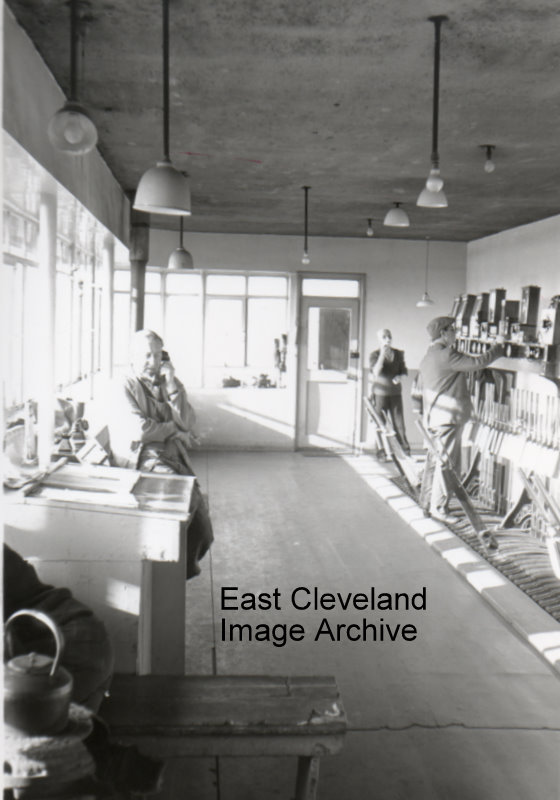

Tod point signal box Warrenby, with men at work.

Image courtesy of Ted Morgan (via Eric Johnson).

|

|

||

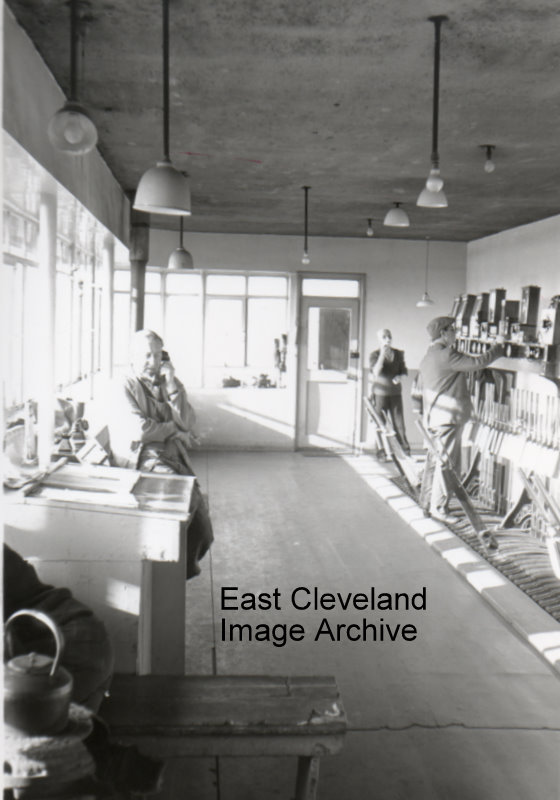

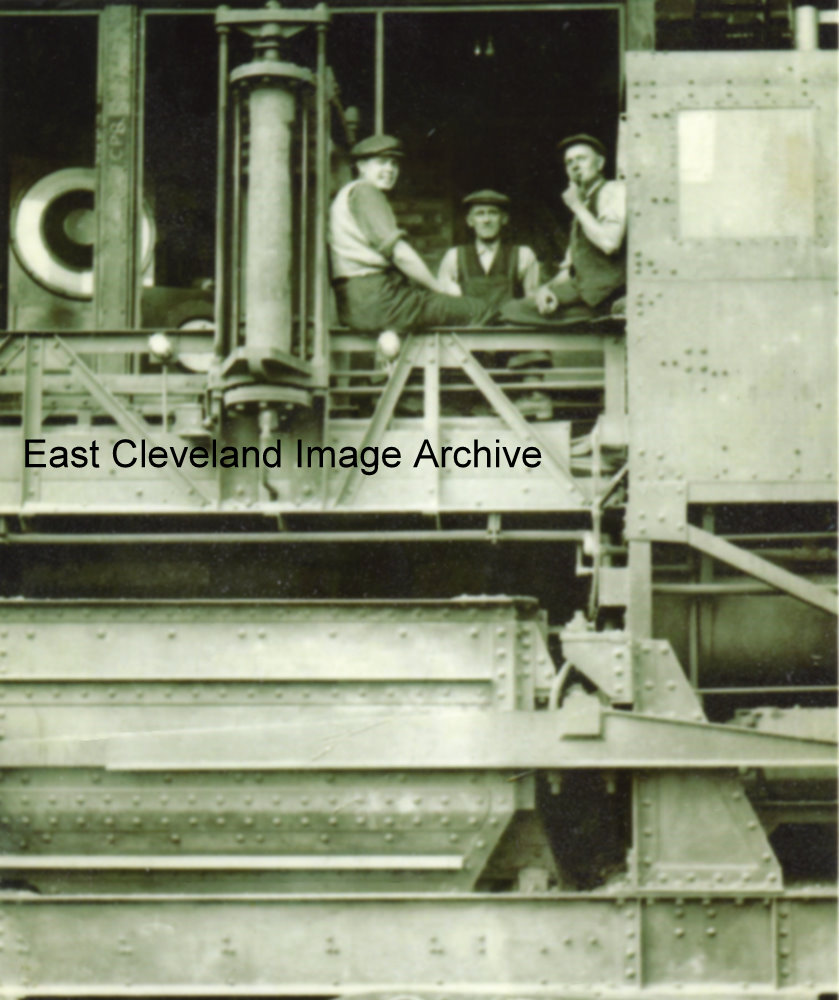

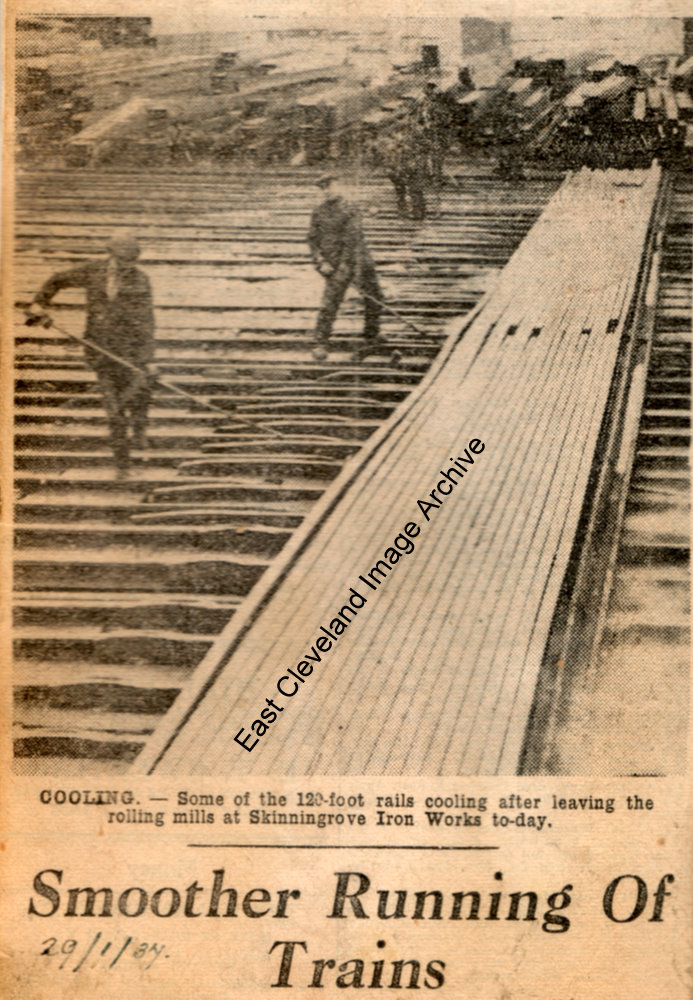

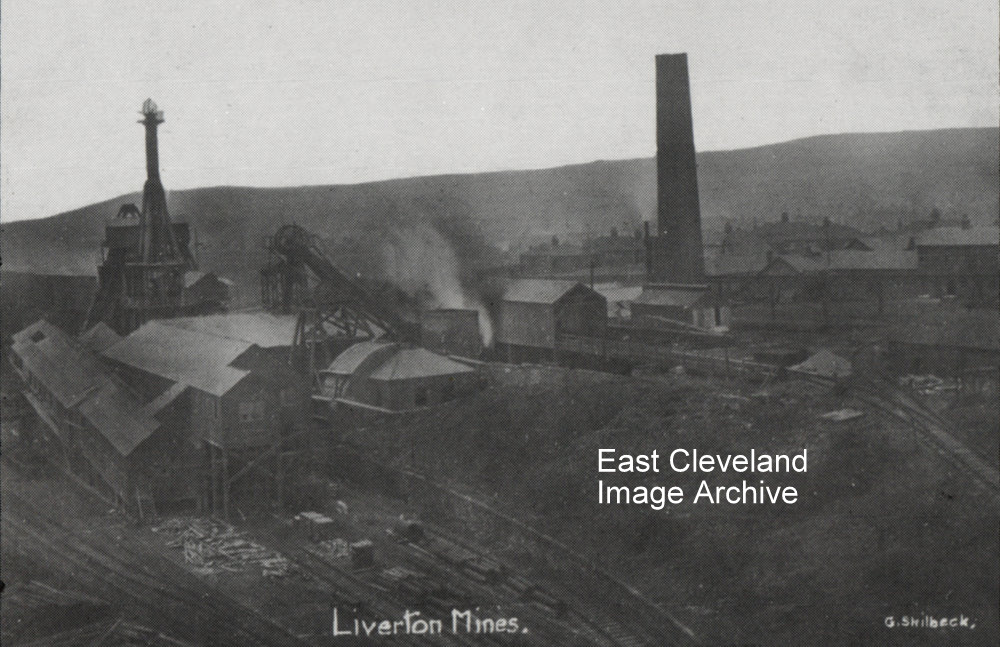

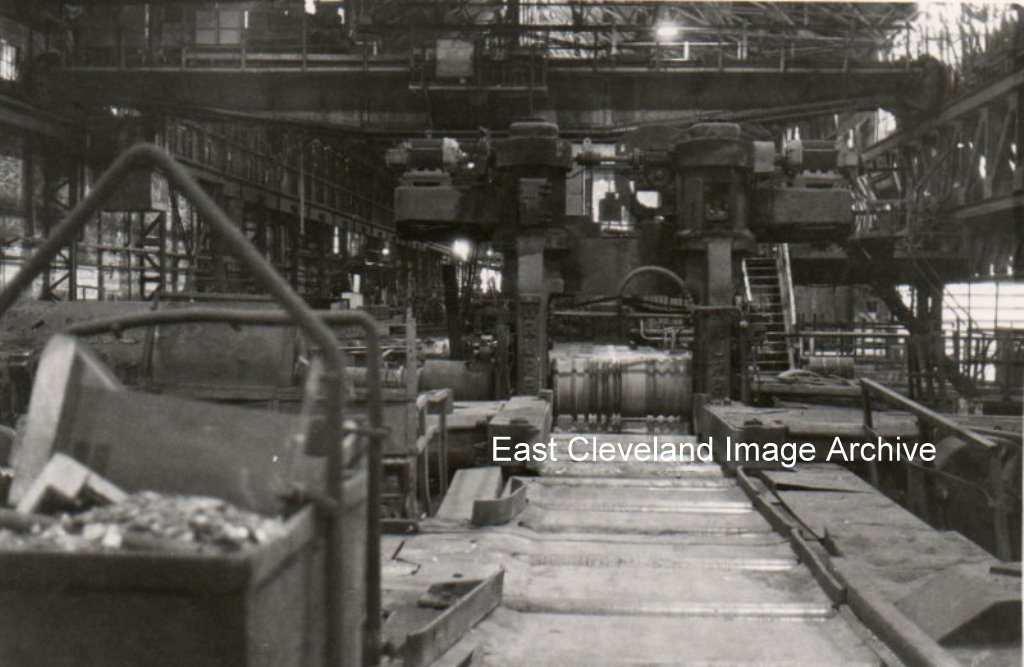

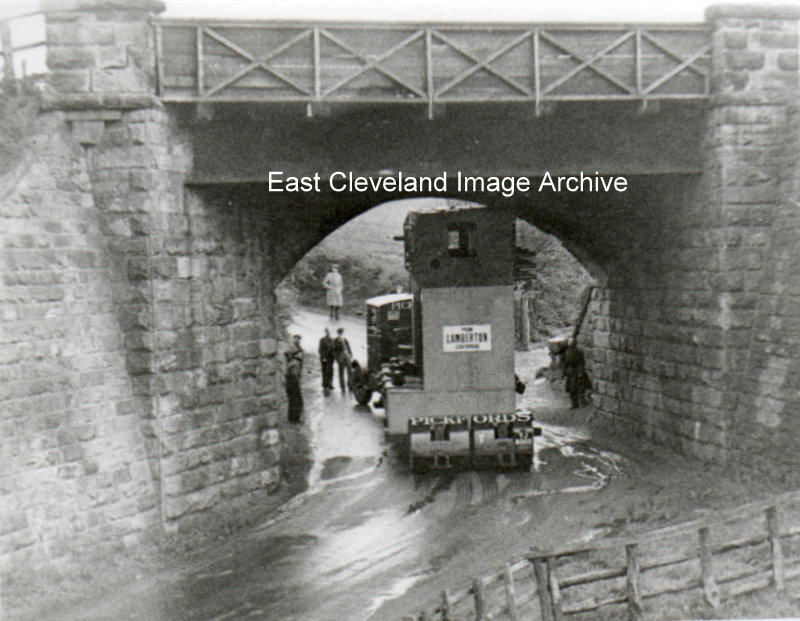

Tod point signal box Warrenby, with men at work. Image courtesy of Ted Morgan (via Eric Johnson).  I know that the gentleman on the left is Frank Liddiard, but who are the other two men and where on Skinningrove works are they? Eric Johnson believes: ”This may be the location of the scale charging car, on no 5 furnace. The large round object on the left might be the weighing scale, for weighing the charges from the materials bunkers ore/ coke/ limestone, and then taken to the skips for hoisting to the furnace top.” Steve Partlett confirms with: “This is No5 Blast furnace scale car. As Eric states, the dial to the left and behind the men was the indication for the weigh hopper below the men. The item behind Frank is the air jack for opening the bunker gates required to allow ore to run into the hopper. As far as I remember there were four of these jacks, so a mix of materials could be loaded into the hopper, in shorter time. The Scale car was driven from the shelter to the right of the men. Although hidden from sight under the furnace bunkers, it was a cold and windy machine to operate in winter.”  Laid at Holme near Peterborough, twice as long as standard sections used by the London & North Eastern Railway, hoping for smoother running of the trains. On account of their additional length and weight – they are the longest in the world manufactured in one piece – have given rise to new problems in handling, the question of expansion is one that will have to be carefully watched. This was taken from an old newspaper dated 29th January 1937. Cutting from a collection gifted to the Archive, most of the cuttings coming from the Northern Echo and cover the period 1930 to 1940.  A George Skilbeck postcard of Liverton Mine, sunk by the New London Company about 1871 and closing in 1923, the eventual owners were Cargo Fleet Iron Co. Southbank. That answers the question often posed as to why Liverton Mines was often referred to as New London. George Nicholson comments: “I’ve lived at Liverton Mines since 1967 and still cannot believe the work that went on there. I will never understand why thy decided to cover the shale tips. Apart from the history of the area they made nothing but a mess.” Image courtesy of Joan Jemson, thanks to Mark Nicholson for the update.  I have been informed by Eric Johnson: “This photograph is of the 32 inch breakdown stand, on the 18 inch mill. It was a war reparation from the German Krupp’s Works after World War II. Image and information courtesy of Eric Johnson.  A tight fit for the Lamberton under Kilton Bridge in 1950, as the new equipment was being transported into Skinningrove Works via the most practicable route possible. Dave Jackson tell us: ”The machine in the image a Lamberton RSM was scrapped in December 2008. It was replaced by a new Danieli RSM manufactured in Udinese Italy and this was installed Jan 2009.” David Park has enquired: “Hello, fascinating site which I happened across. Would you possibly have any details of how the Danieli RSM arrived back in 2009 please? In a previous employment an Italian freight company approached us about delivering it, but it became clear they had ignored warnings that the bridge over the railway was unsuitable for the weight! I came to Skinningrove works to try come up with a solution, but we fell out with the Italian firm due to their desperate attitude. Thanks in advance.” Can anybody assist with this query? Image courtesy of Eric Johnson; thanks to Dave Jackson and Andy Park for the updates.  The view from Todd Point signal box at Warrenby Redcar.  The Talbot furnace at Skinningrove works. Eric Johnson advised: ”A view of the front side, of a 120 ton Talbot furnace. The charging pans on the right contain (galley) iron ore, on the far side of the furnace the pans contain lime. The furnace doors are water cooled, added after oil firing was introduced. To the left of the Melter, in front of the door is a stand used for the hot metal chute.” Does anyone know the name of the gentleman standing rather close it looks to me.  Excavating the new reservoir for Skinningrove works. Steve Partlett tells us: ”Part of this reservoir still exists. It was on the edge of the cliffs, to the north of jetty bank top. One of it’s purposes was to provide storage for No5 Blast furnace cooling water. The concrete block in the middle of the photograph was where the pipes left the reservoir to feed the pumphouse which was built just in front of the block. This probably means the photo was taken sometime during the building of No5 Furnace, (early fifties, I think)and was possibly taken from the top of one of the older Blast furnaces. There was also a large tank supported on a steel trestle in front of the mound in the lower right of the photograph. This provided the “head” of cooling water for a while in case the pumps failed. A Laboratory was built into the steel support trestle. Due to it’s height this tank was visible from the beach below.” Image and information courtesy of Eric Johnson, thanks to Steve Partlett for the update.  Although it sounds more like a dance than a machine used on the steel works, Brian Young tells us: ”The Lamberton was used to straighten various “raw” steel sections after rolling from the 36″mill. The Lamberton was fed via rollers and skids, after straightening each bar was shoved off onto benches manually.” Tony Shaw assists with: “This is the 53″ Lamberton straightener seven shafts, this machine was recently replaced, the 26″ straightener nine shafts was replaced a few years ago.” Michael Graham tells us: ”We used two of these machines in No 9 mill Cleveland works”. Image courtesy of Eric Johnson and thanks to Brian Young, Tony Shaw and Michael Graham for the updates. |

||

Recent Comments