|

|

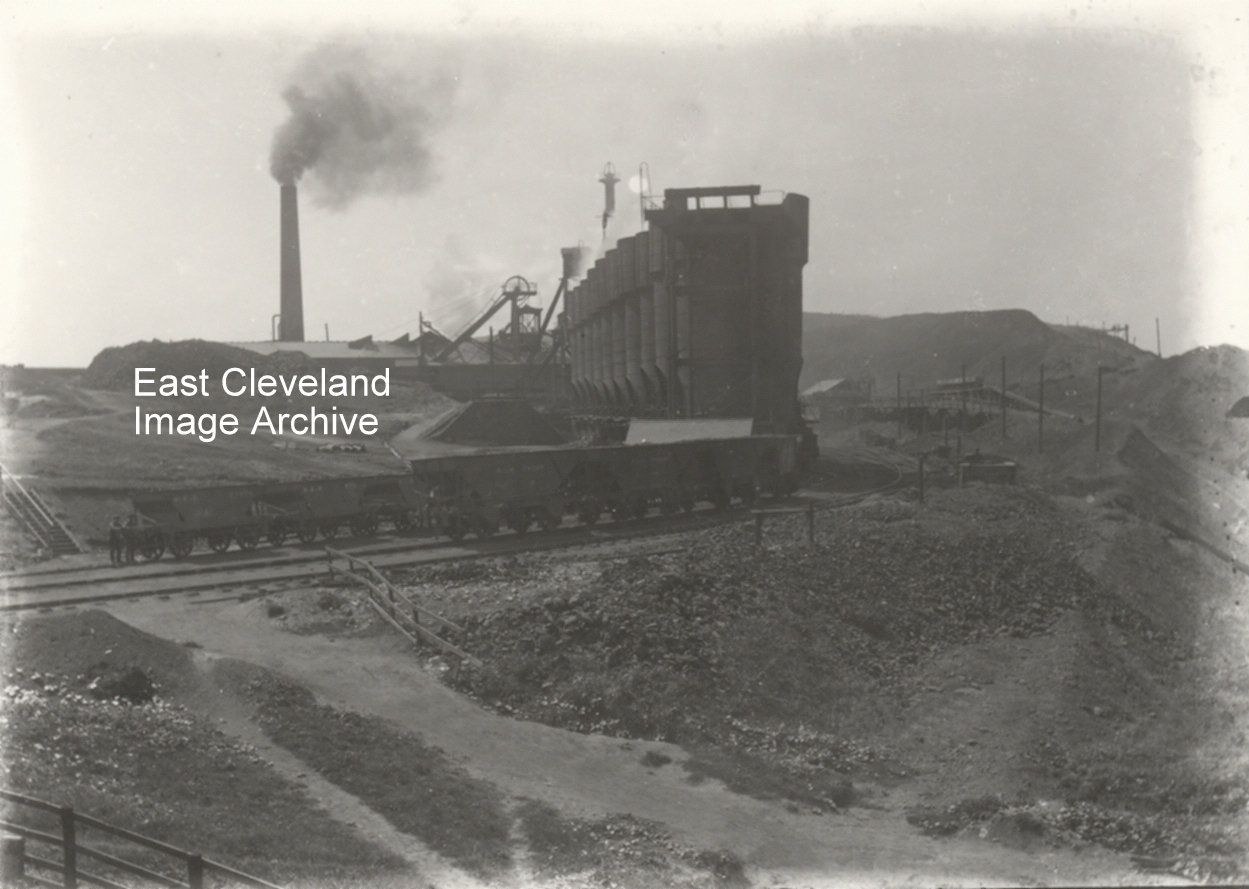

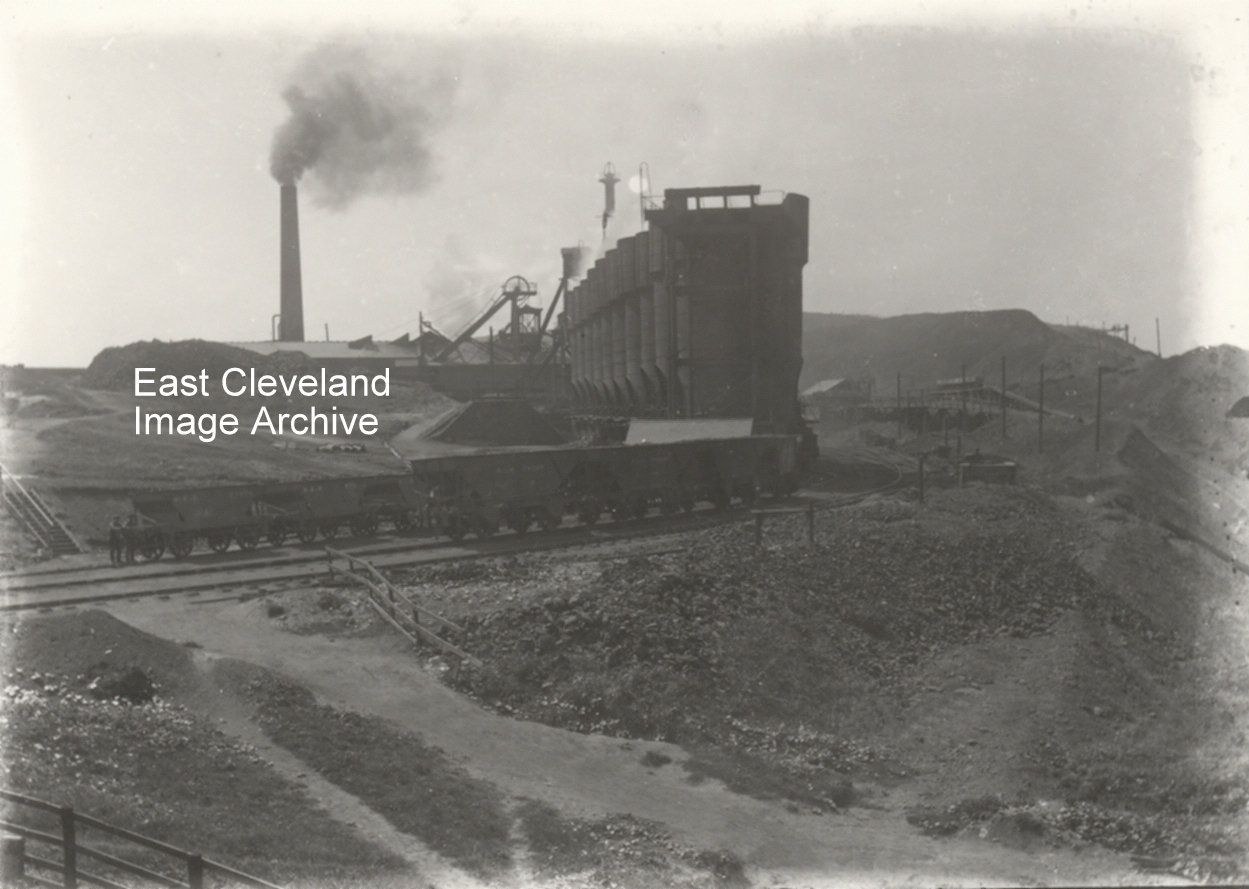

This is a view of the Calcining Kilns at Liverton Mines – which were well-known as being associated with the Ironstone Mine – these Kilns obviously dominated the landscape. Simon Chapman advises: “Railway wagons at this time were generally wooden bodies but couldn’t be used for carrying hot calcined ore which is why the N.E.R. built a fleet of steel wagons specifically for this traffic; a few can be seen to the left. In front are more steel wagons, built about 1906 to hold a greater tonnage”. Russ Pigott asked ”Were the larger steel wagons in the picture fitted with vacuum brakes? There seems to be a vac cylinder mounted above the sole bar on the end of the wagon. This would seem a bit strange as not many locomotives used on these trains were fitted for vacuum at the time”. Answered for us by Simon Chapman: ” Well spotted, Russ! Apparently they were actually fitted with air brakes and run as block trains from Liverton to Cargo Fleet works. This was such an unusual working that I can remember the late Ken Hoole trying to find out more information over 30 years ago. Note the large drum shape above each axle box on these larger wagons – some form of friction reducing roller which can’t have been very successful otherwise it would have become more common.” Russ said ”I thought the drum shape was the operating wheel for the hopper doors. What locomotives were used on these trains, I think most J21s were Westinghouse fitted but the J26s and 27s had no train brakes. That poor remaining J21 sits a mere couple of miles from me looking ever more like a Barry engine!”

Thanks to Russ Pigott for the updates and many thanks to Simon Chapman whose information is invaluable to all who visit the site; Simon also thought it was: “A very atmospheric picture!”.

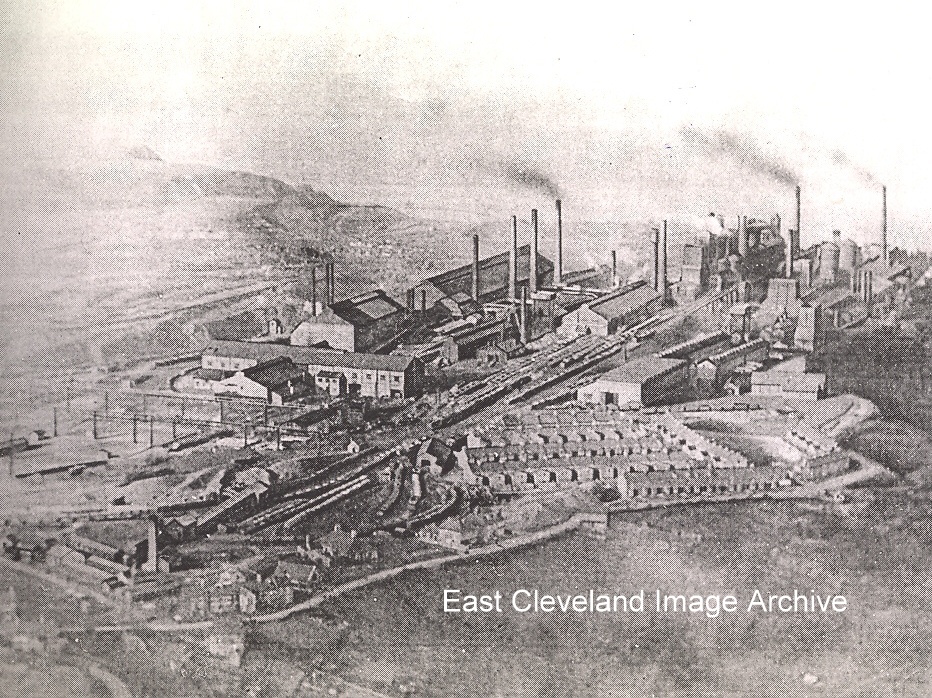

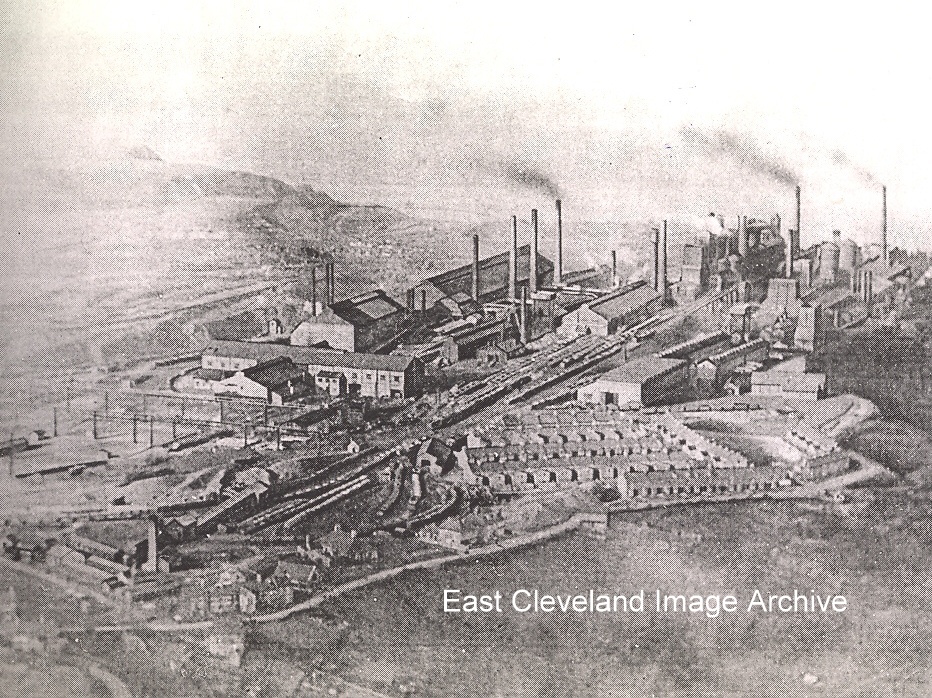

Here is an early aerial view of the works – dating from 1920 – more smoke in this image than in the others! Also of interest in this image, the buildings in the lower left of the view are of North Loftus mine.

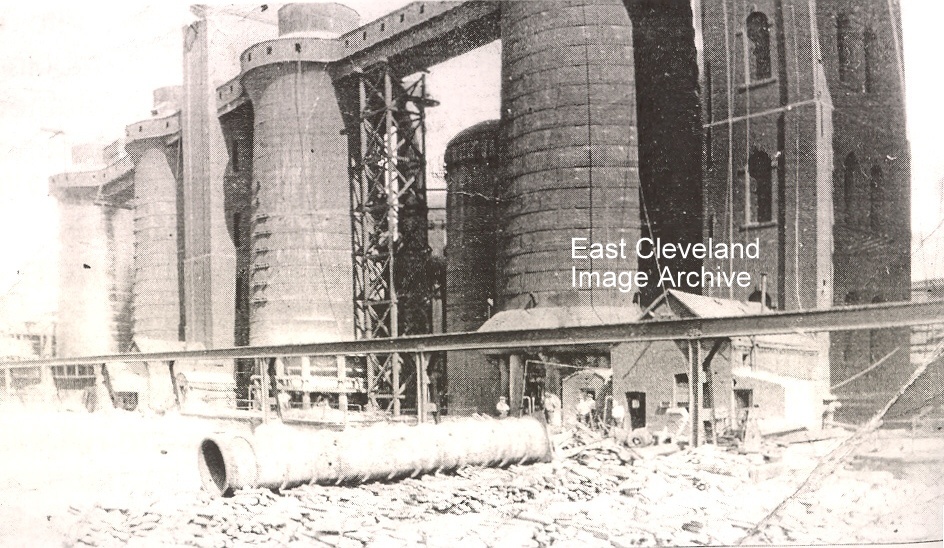

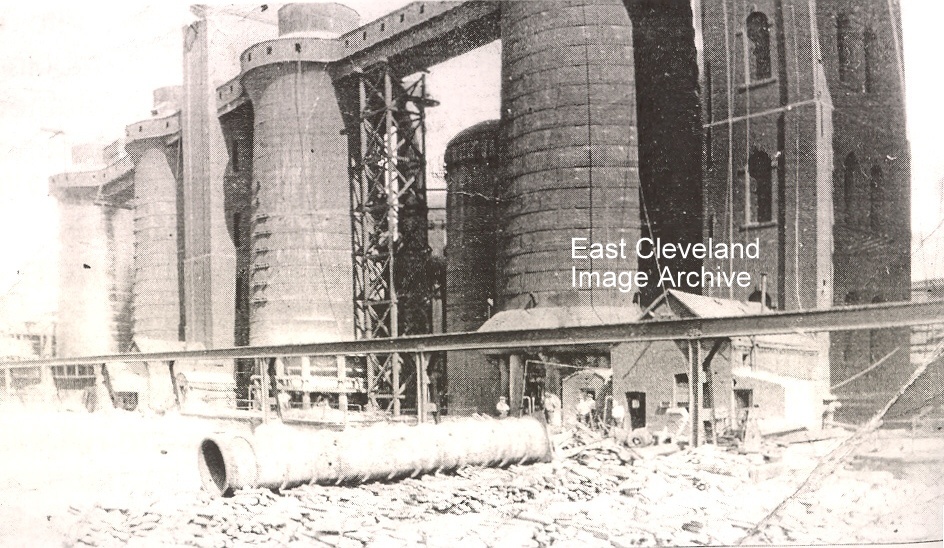

Not the shot of the blast furnaces that we usually see, but this shows more of the heaps of pig iron awaiting disposal; not sure what the large pipe section is though!

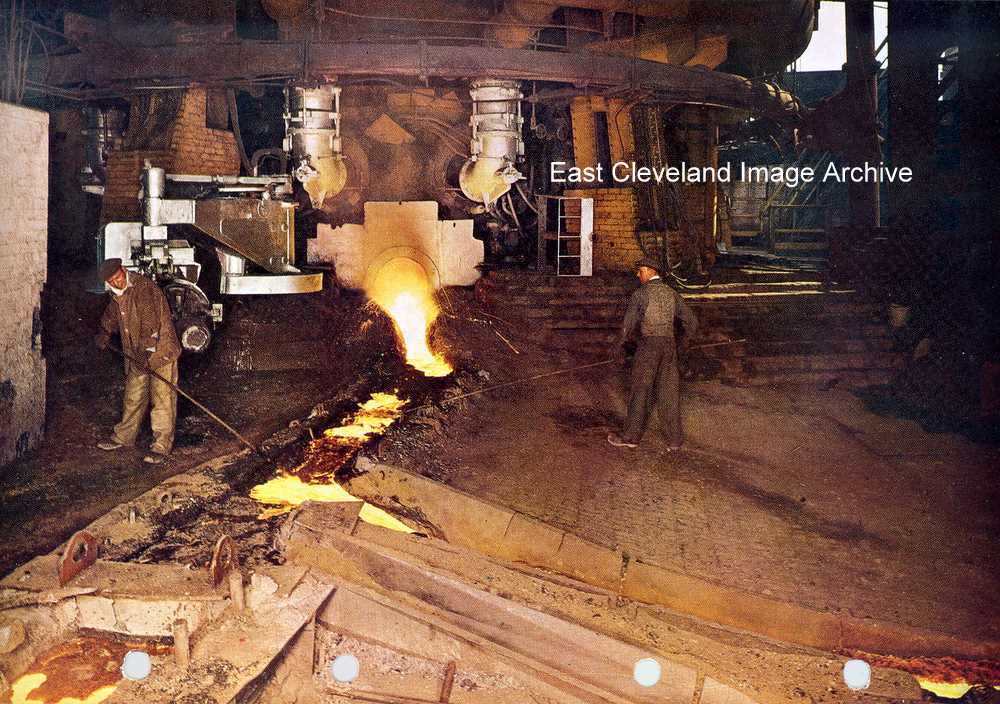

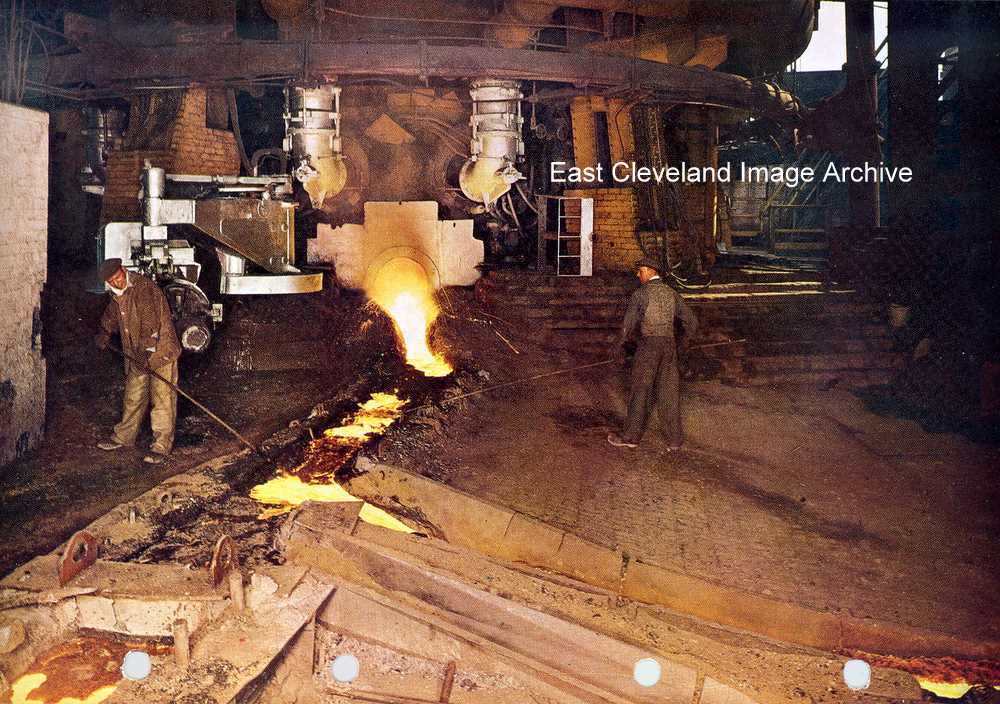

A modern view of a no. 5 casting; Bob Proctor tells us: ”If you ever wanted to view the inside of the furnace then you would use the eye piece, this is at the bottom of the silver goose-necks and looks like a protrusion. You would firstly make sure there was no leaking hot blast (500C) by moving your hand over the toughened glass eye-piece and then you could see through the blow pipe and tuyere into the heart of the furnace where the droplets of slag/iron cascaded down through the incandescent coke.” All working furnace-side wore blue glasses, otherwise their eyes would feel the pain! If possible using a sweat-rag, not their hand – 500C is not good for the skin! – but well-worth taking the precautions, it is a beautiful sight. The glass eye-piece (mica initially, then toughened quartz glass is called a pee-pee.

Thanks to Bob Proctor for the comment.

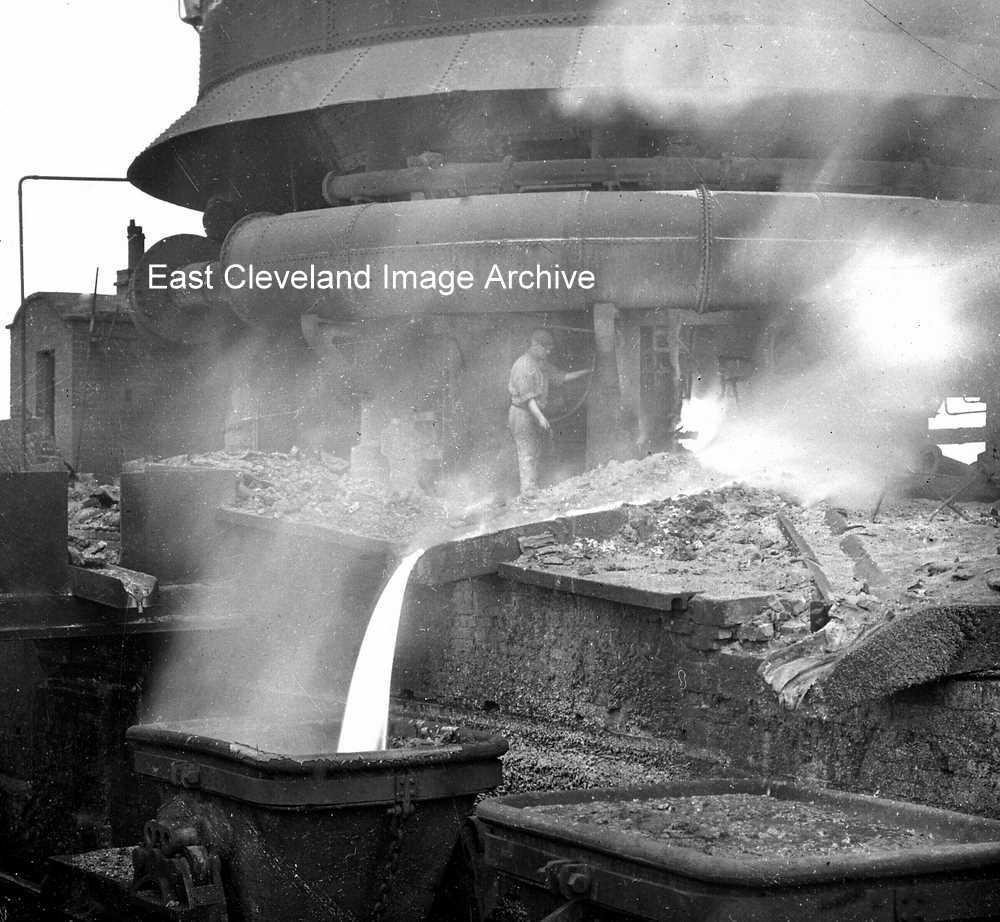

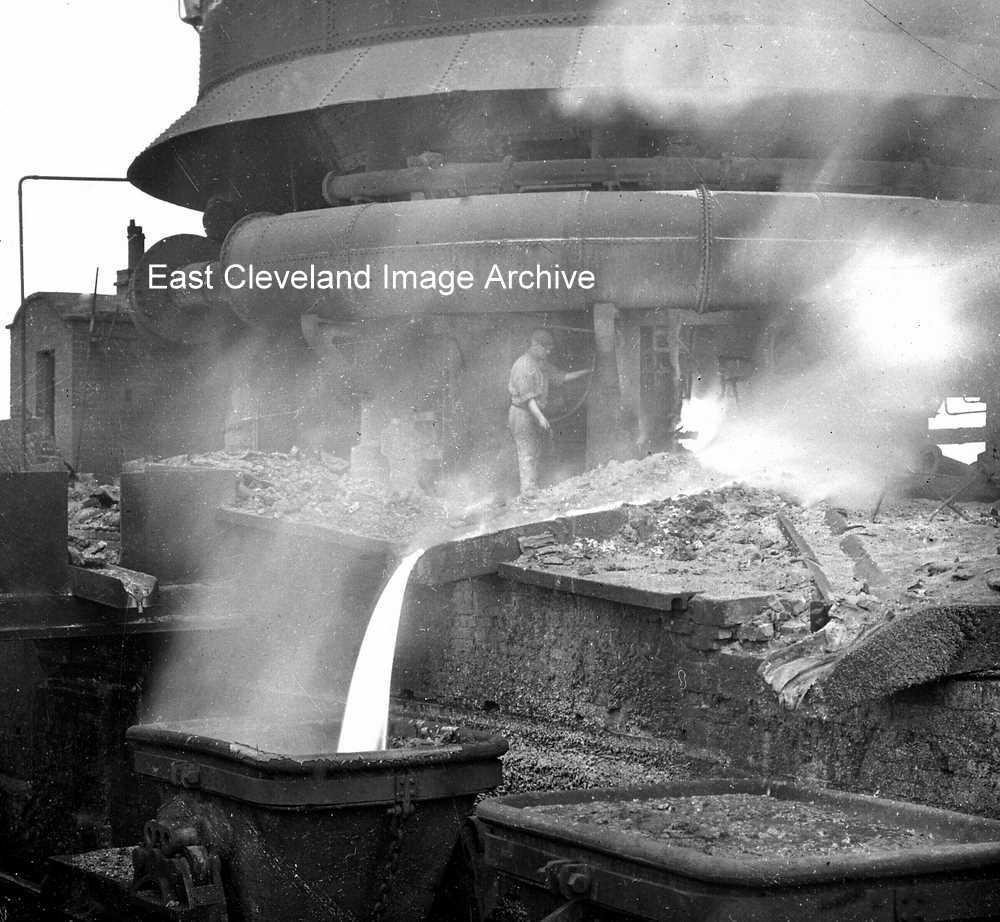

Here’s a slag pot being filled after the iron has been run off, does this brings back many memories?

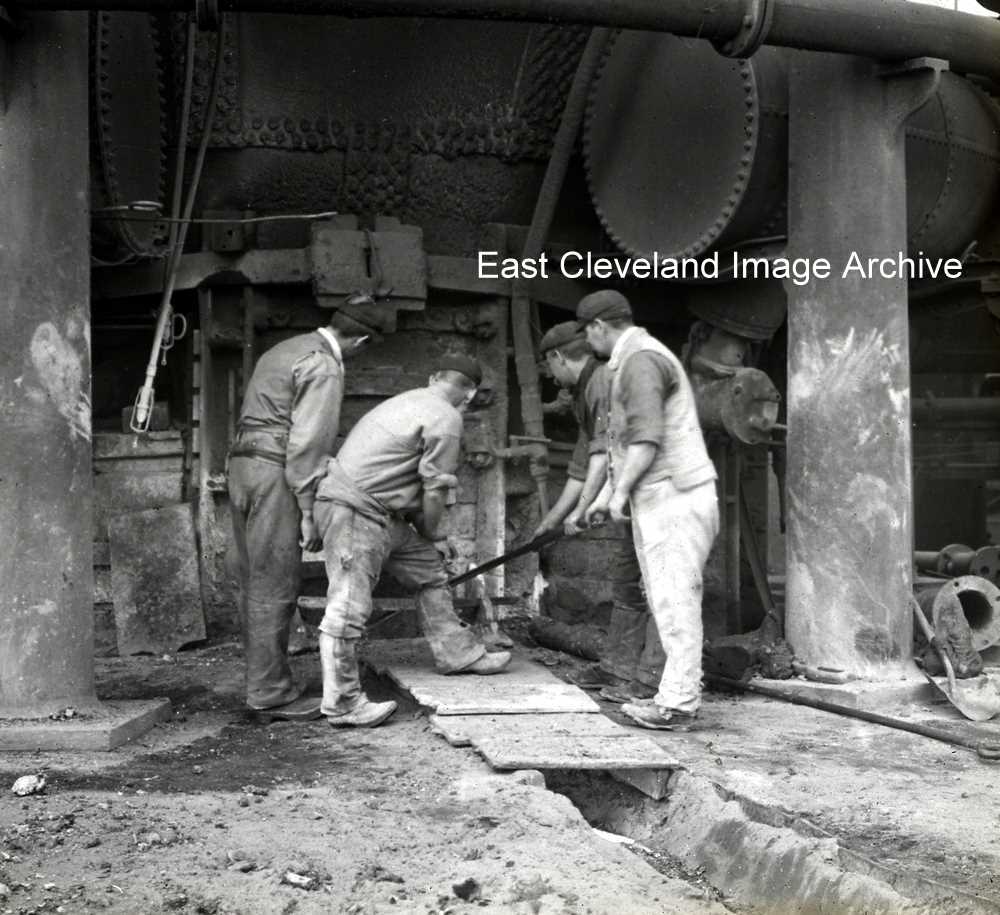

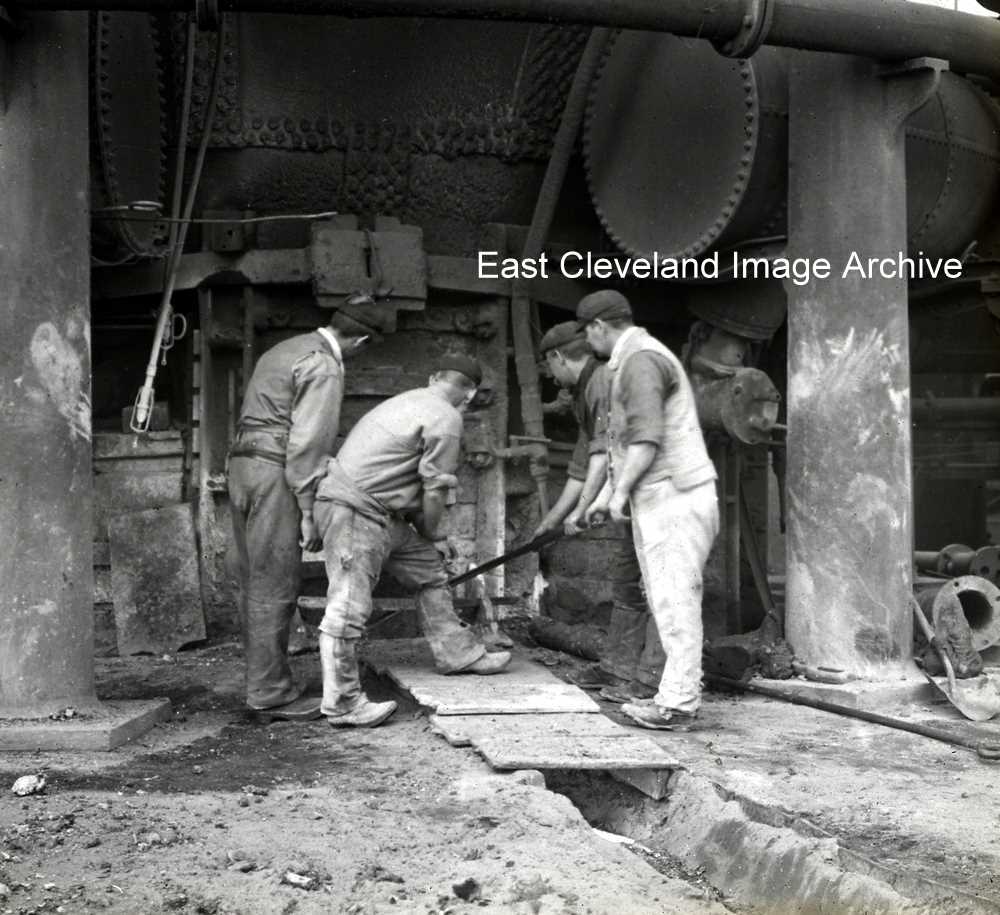

This is one of the older furnaces at Skinningrove with the crew barring out the tap hole; possibly ”Slaggers and Pig Bed Crew” in Skinningrove works. This must be quite an early photograph as none of the men are wearing a safety helmet. Middle man front row has his feet in ”Sow” channel for the molten iron.

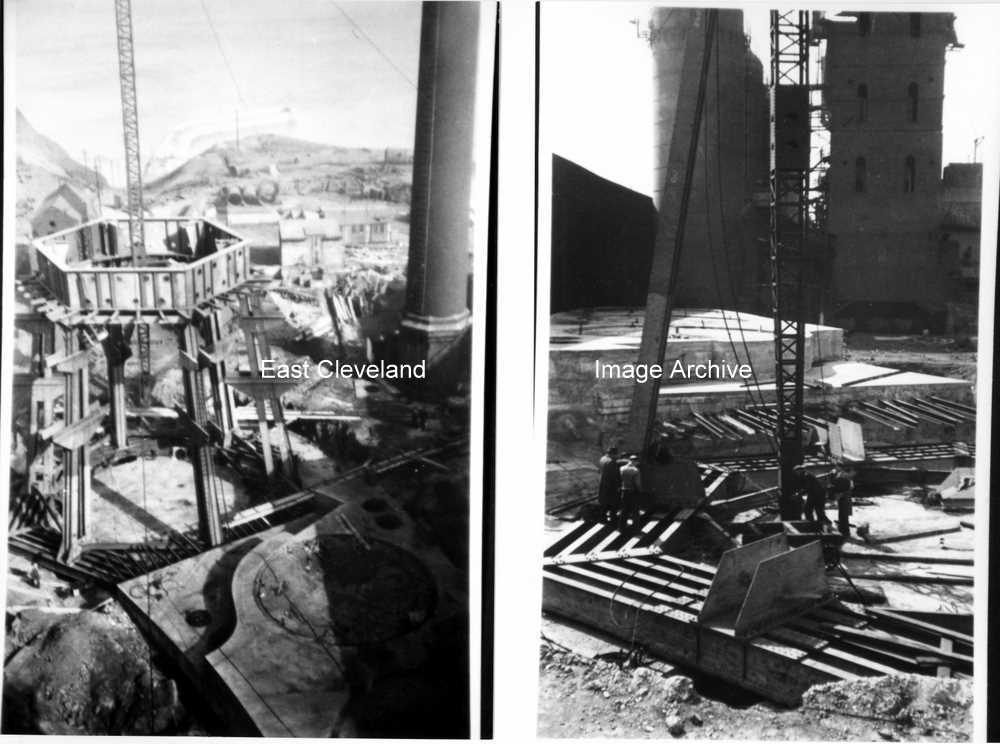

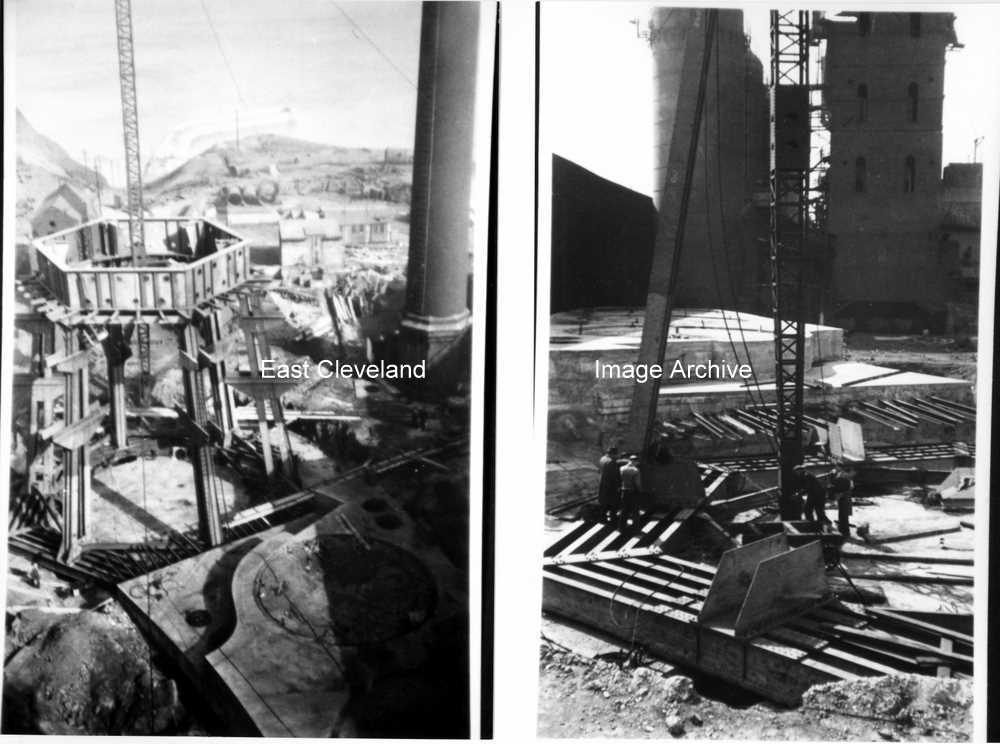

This shows the steel-work being erected that will eventually contain the structure of No. 5 Blast Furnace. In the left hand image, the shape at the bottom right is the hearth structure. This feature was the hardest part of the furnace to remove after it was toppled, being constructed of solid carbon blocks.

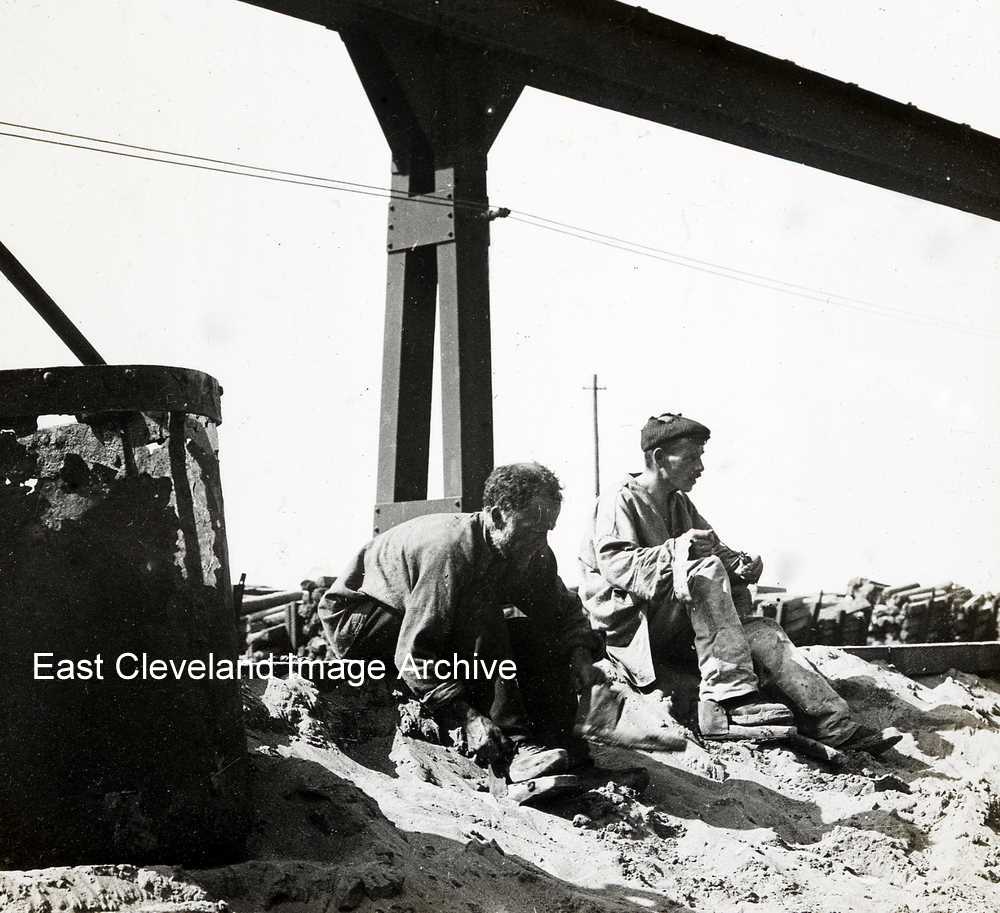

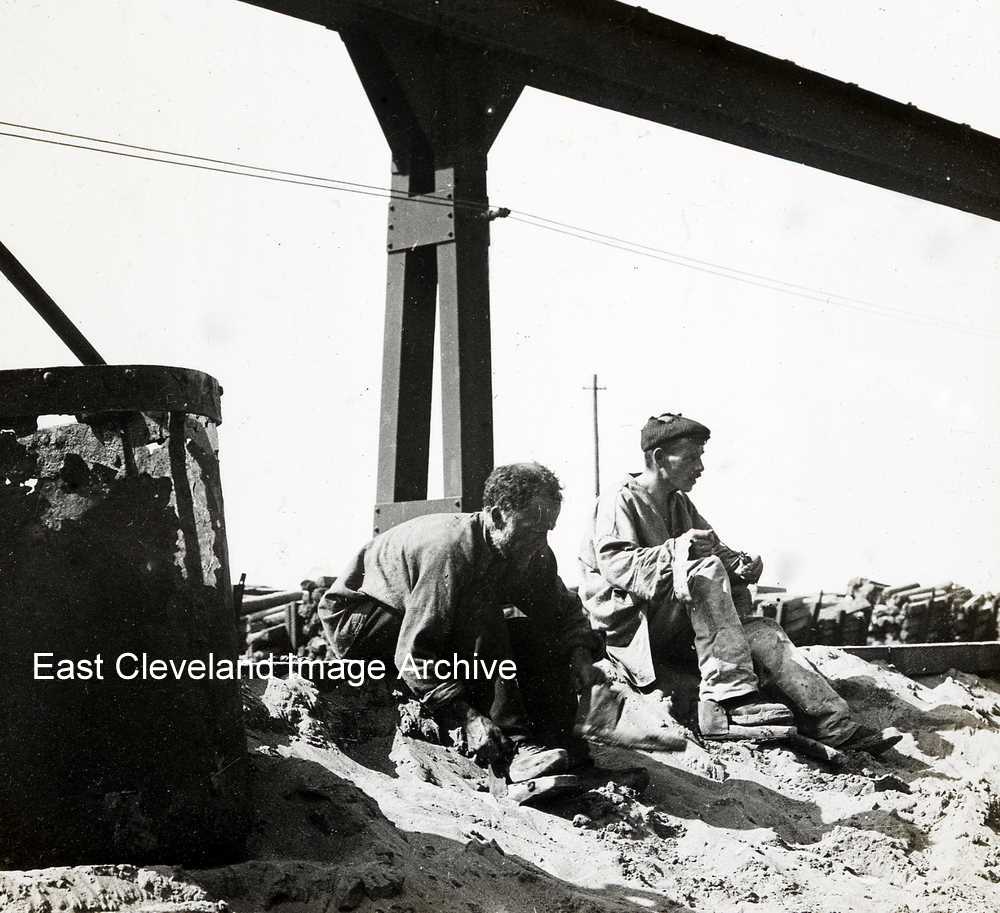

This image (pre-1950) shows the left-hand man strapping on his clogs – shaped wooden soles to protect his rocker boots from the heat – before going in to do some hot work on the casting floor.

An image of a stack of pigs being stock-piled. The bar in the labourer’s hand is to break the pigs off the sow.

When the furnace has cast, the pigs are attached to the sow and the crew have to go around and break them off and heap them together in slings to be stock-piled.

|

|

Recent Comments