|

|

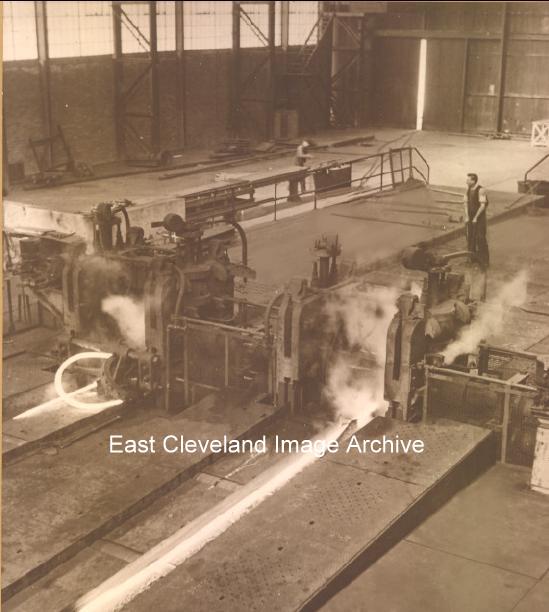

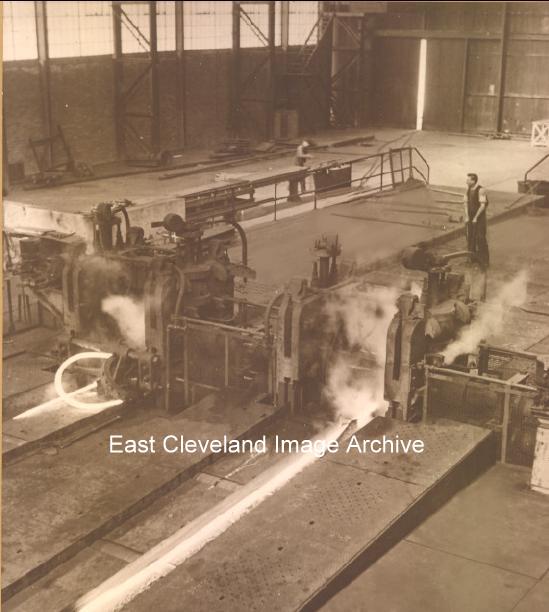

The Archive was not sure which stand this was in the 18” Mill and wondered if someone could enlighten us? Raymond Stonehouse assisted with: “I believe this view is of the Intermediate and Finishing Stands, looking at them from the Saw side (North Sea)”.

Thanks to Raymond Stonehouse for that update.

The same applies here, it was almost a taboo place for the uninitiated, the steel used to hurtle around on the mill floor – very scary!

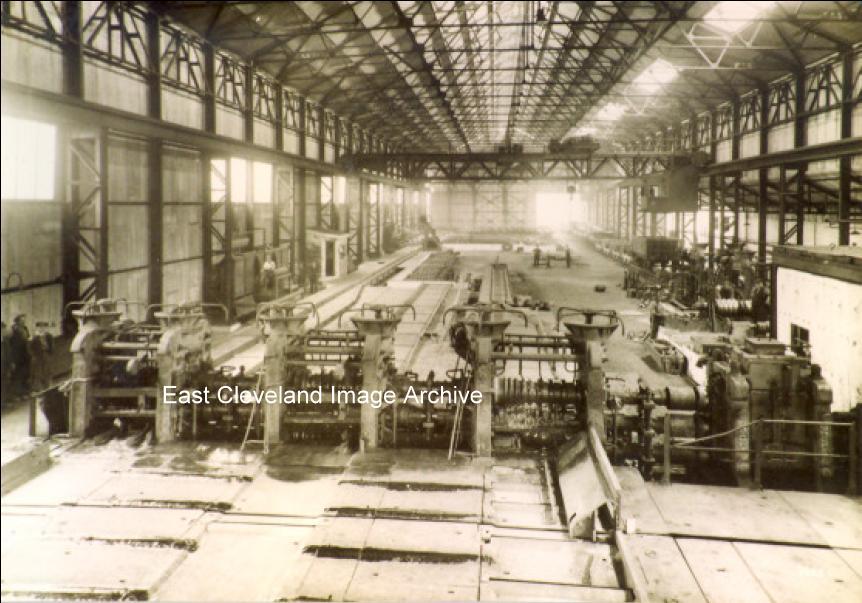

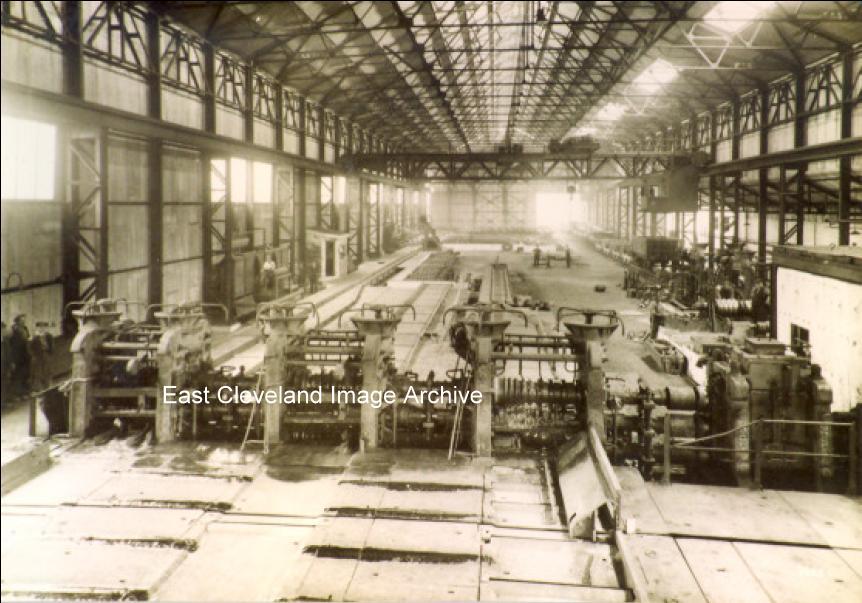

A view down the shop of the 18 inch mill before re-modelling in 1956.

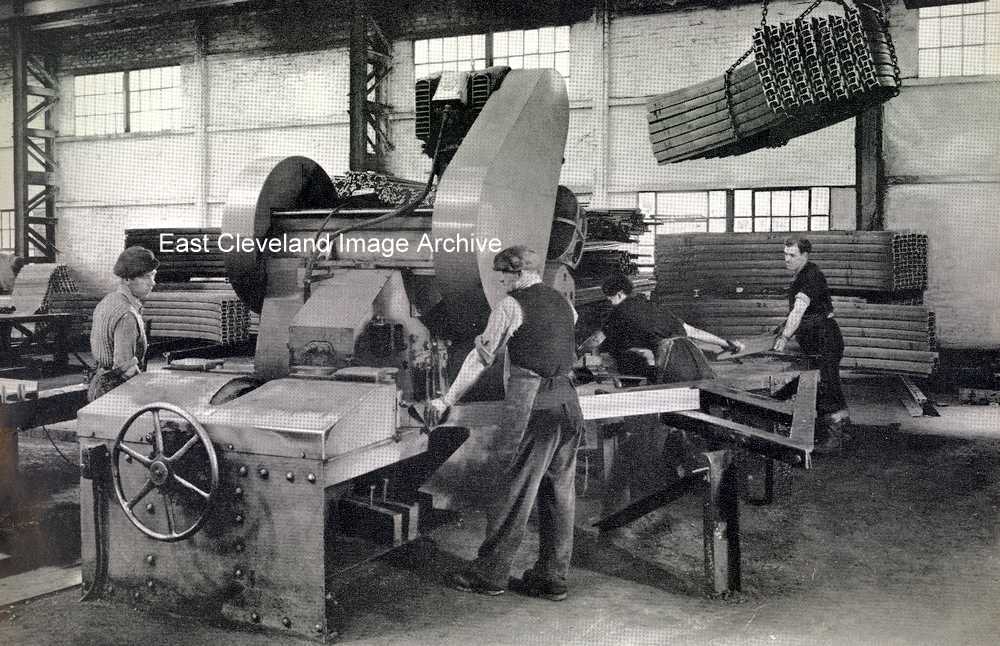

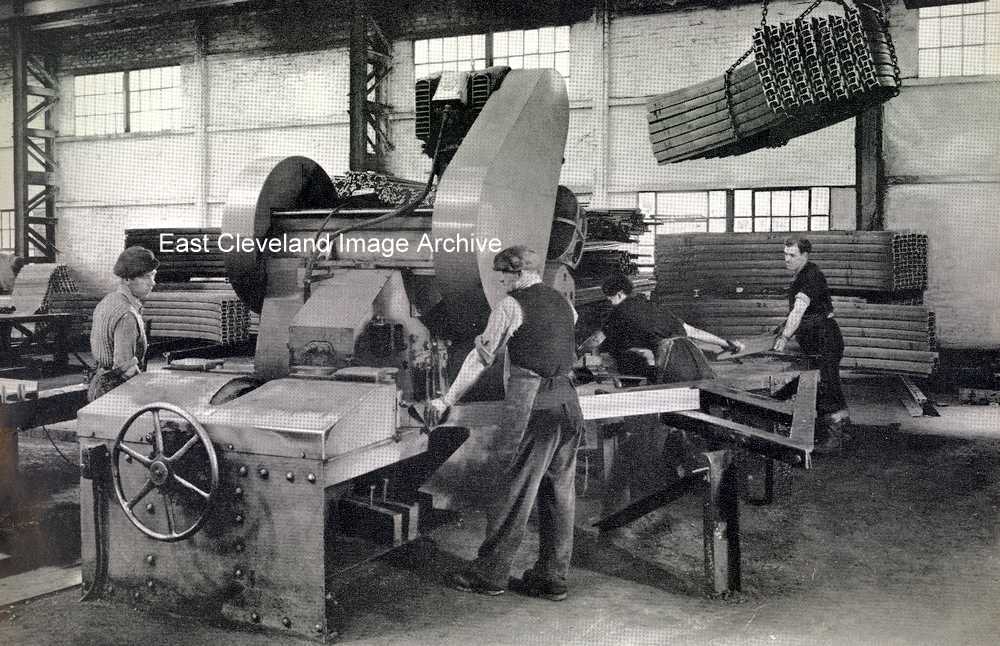

As the mining industry modernised the coal mine in particular moved across to steel for its roof supports and Skinningrove was quick to capitalise on this; the 18” (or Little) Mill being ideally suited to producing small ’H’ beams (or ’I’ beams, if you prefer) and as the order book grew so did the Colliery Arch Department. They were all cold-formed on these rotary bending machines. Frank Bridge advises:”I worked on this very machine back in 1973-1974, a memory worth holding on to. The men I worked with were the hardest grafting and drinking crew you could wish to meet; a truly great bunch of lads”. Eddie Watson adds: “I worked in colliery arch plant B.S.C. Cleveland.from 1975-1986. I worked my way up from stick lad on cropping machine to cambering machine puncher. Very hard work but best times of my life”.

Thanks to Frank Bridge and Eddie Watson for the updates and memories.

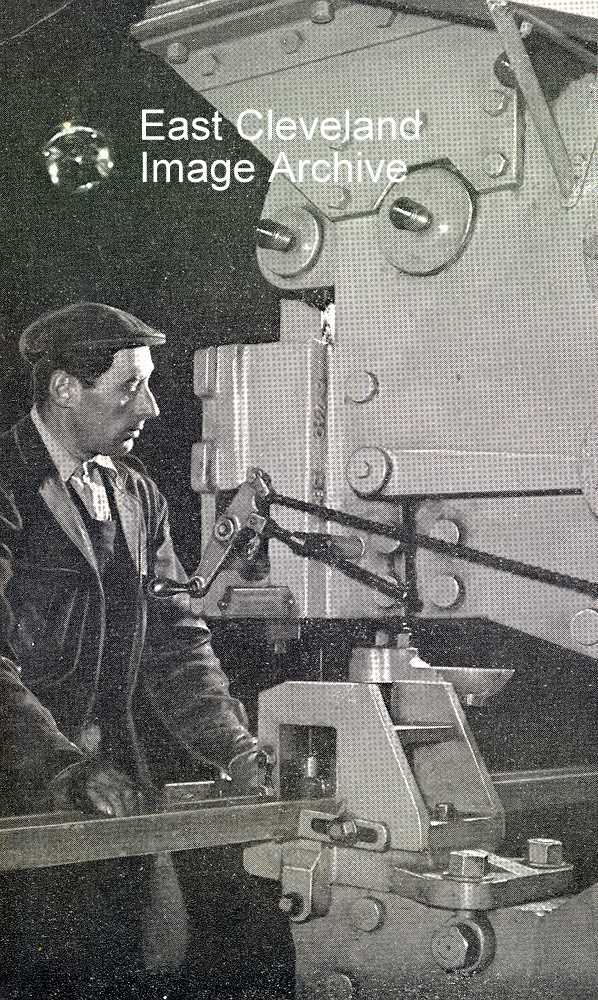

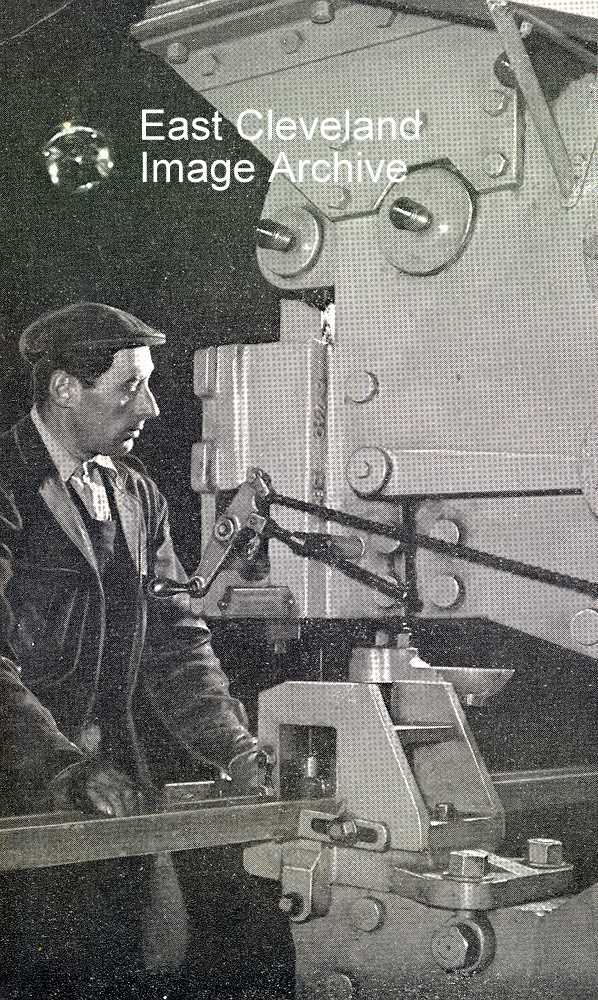

How do you make perfectly finished squared ends to your steel products – with a cropping machine like this.

Image courtesy of the Pem Holliday Collection.

The rotary tippler at Skinningrove Iron and Steel Works. Rodney Begg told us: “When this plant was working my white collars would turn a paler shade of grey in no time!”.

Image courtesy of the Pem Holliday Collection and thanks to Rodney Begg for the update.

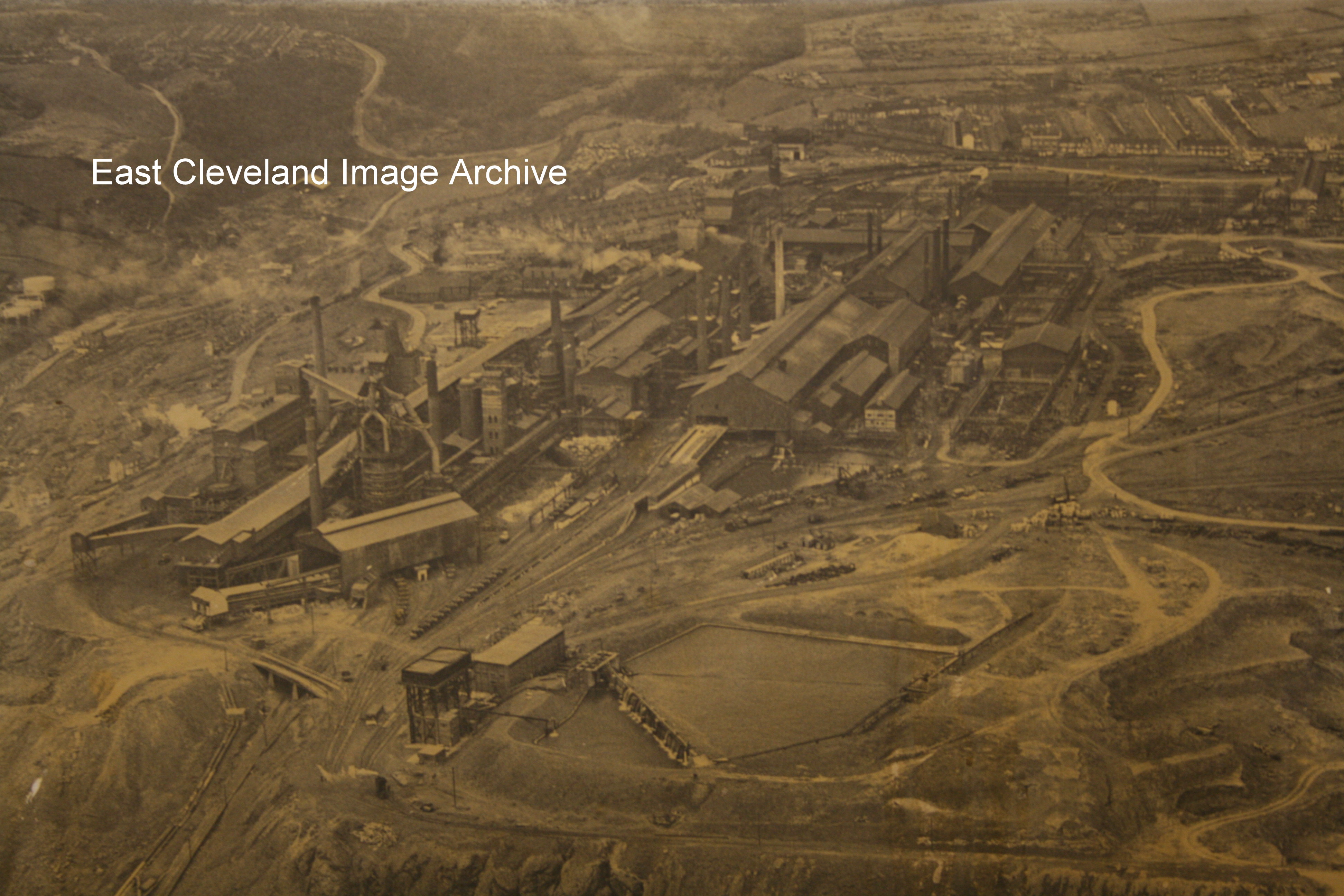

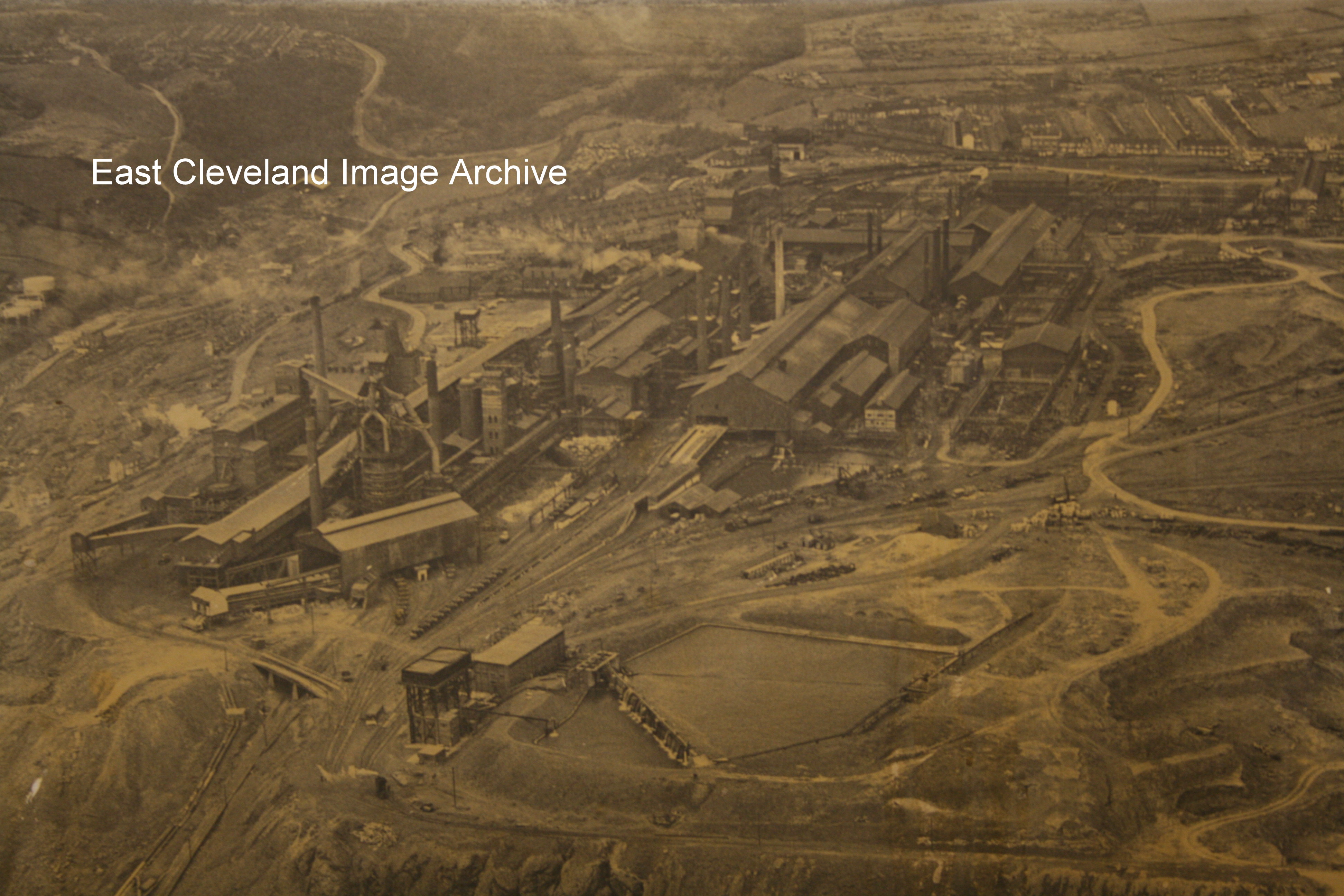

As Rodney Begg told the Archive: “This is the Skinningrove I knew and loved! In the foreground, under that water tower was the fuel laboratory (upstairs) and the day laboratory (downstairs). I spent my first twelve months on the ‘Grove’ as a junior chemist here”.

Image courtesy of the Pem Holliday Collection and thanks to Rodney Begg for the detail.

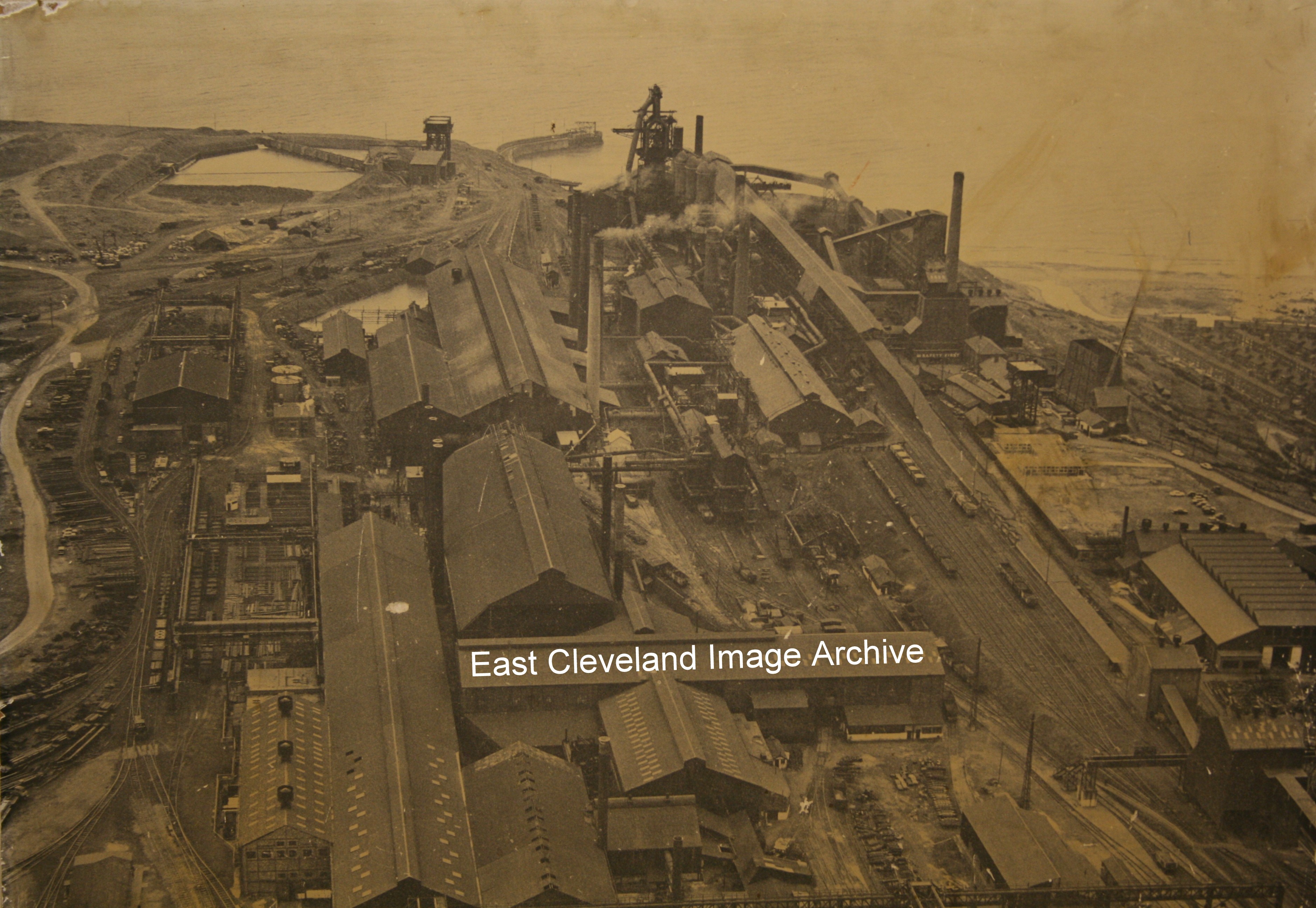

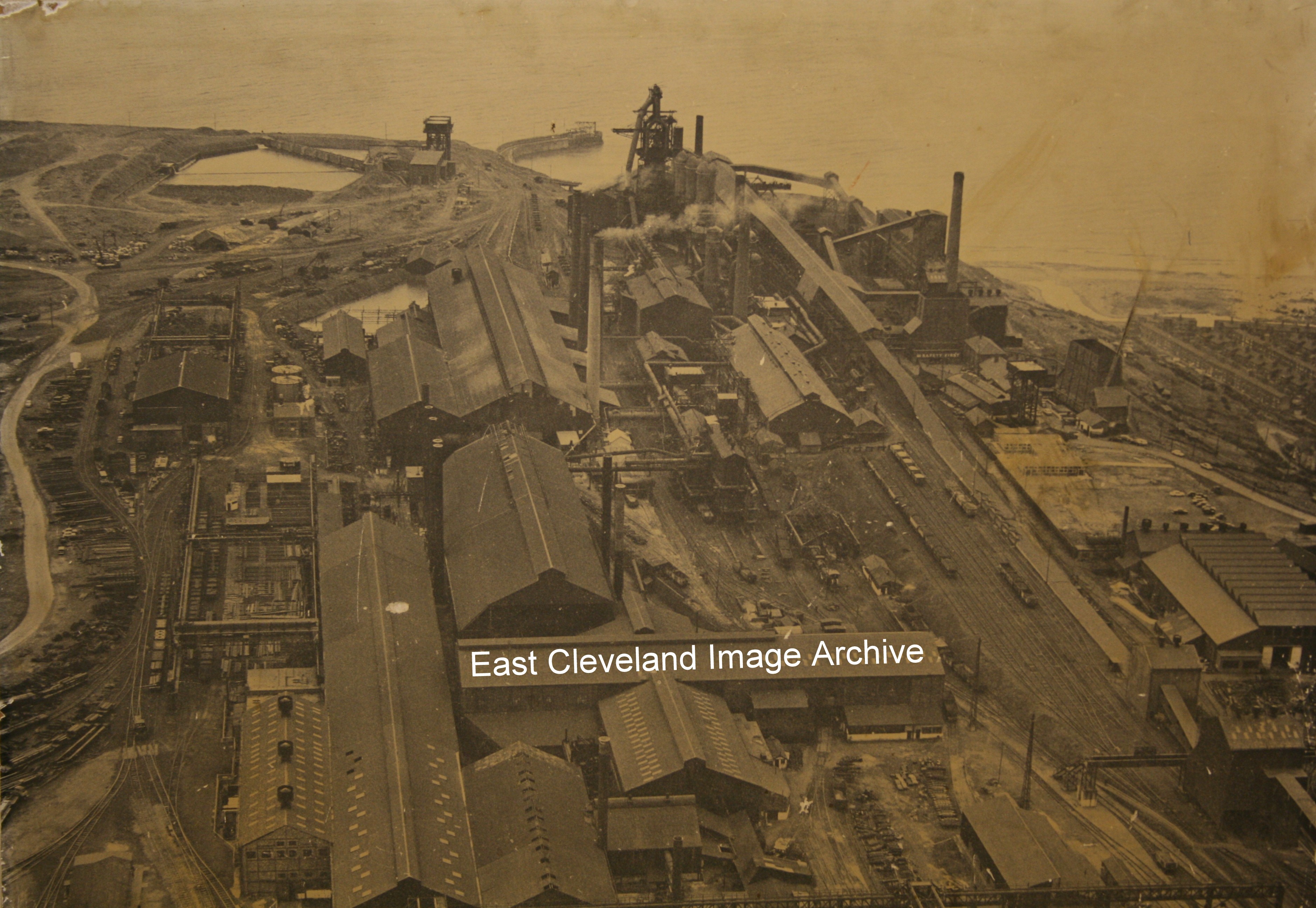

Viewed towards the sea this time; the Talbot’s with its four smoking chimneys; Rodney Begg told the Archive “I spent about nine months on the shift lab with Stan Agar and learned to weigh off a sample of slag or iron – while the scrap kibbles rolled past – no mean feat!”. Malcolm Moore advises: ”My dad was a first hand on the Talbots, he retired (pensionless) about 1970. The Works did him no favours!”

Many thanks to Malcolm Moore for that update.

A completely emasculated Skinningrove steel works now; almost a green field site, merely a merchant mill producing special sections to feed the plant that has sprung up mid-left of the image – Caterpillar. Not forgetting all of the other special sections made here of course!

Image courtesy of Owen Rooks.

You had to watch out for these – they had a habit of sneaking up on you when you were crossing the floor!As Vic Nicholas advised after a mistake in the original commentary: “That is an ingot coming out of the Salem Bloom furnace it would be going direct to the 42″ breakdown mill (Cogging) before it goes to be either reheated or skidded direct to the mill. Can’t roll anything direct from the bloom furnace it’s just to big”.

Image courtesy of the Pem Holliday Collection, many thanks to Vic Nicholas for correcting our original error.

|

|

Recent Comments