|

|

The photograph shows the stacking machine which was installed around 1992. The machine is fed by rollers with single bars then the feed bank pushes them and turns them before putting them onto a table which lowers to enable the next bar to be stacked. The complete stack is then lifted by the table onto the rollers which passes the bundle through the strapping machine which is then ready to load. Martin Byers is standing in the control pulpit. The section is a Single Grouser that is used for Caterpillar track shoes.

Image and information courtesy of Colin Hart.

The Archive originally posted this image of the 36 inch mill men with a request for names and a possible date. David McGill advised: “left to right: unsure, Bill Rigg, Wally Hall, John Curnow, George Pearson, Dave Hick”. Hugh Bernard told the Archive: “I have just been looking at the images of Skinningrove and came across this picture. The man on the extreme left is my father, John Bernard who was the Rolling Mill Manager. I have a copy of the photograph in the family archives. My father a Scot worked at Skinningrove until his death in 1970”.

Thanks to David McGill and Hugh Bernard for the names.

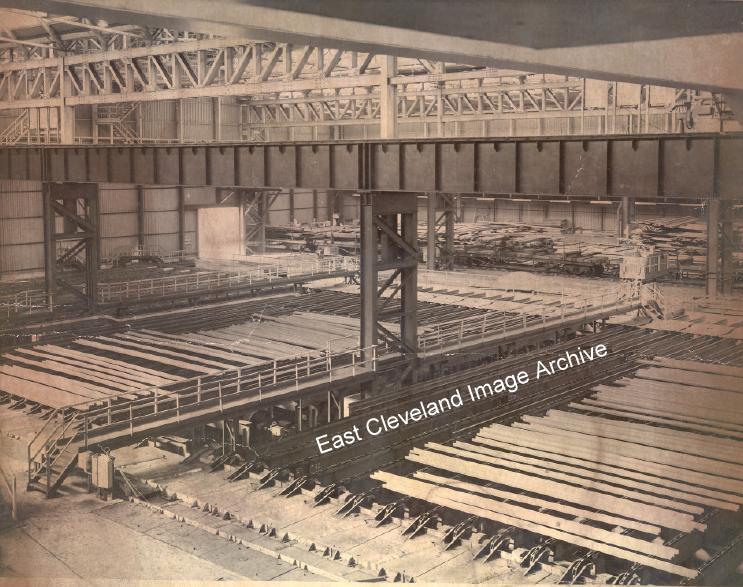

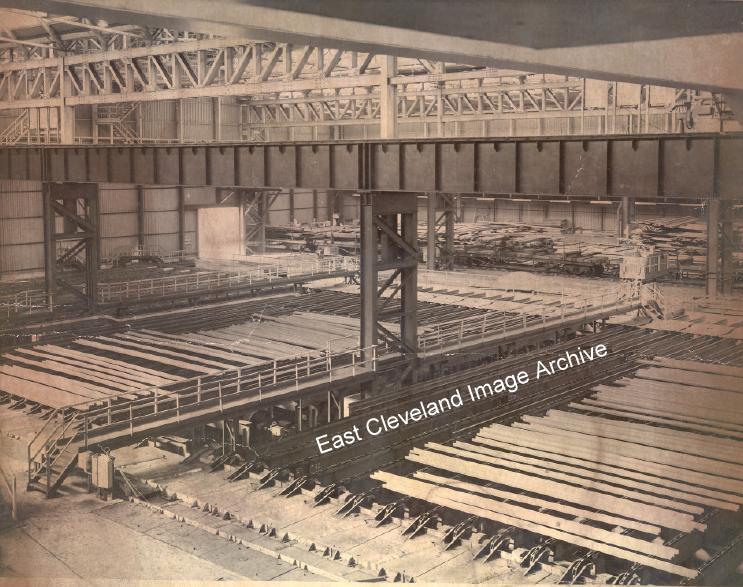

These are the cooling banks in the 36” Mill finishing prior to the Lamberton straightening machine. Colin Hart advised: “The door on the left was later sheeted over (covered) to prevent noise as it was facing Carlin How”.

Additional information courtesy of Colin Hart.

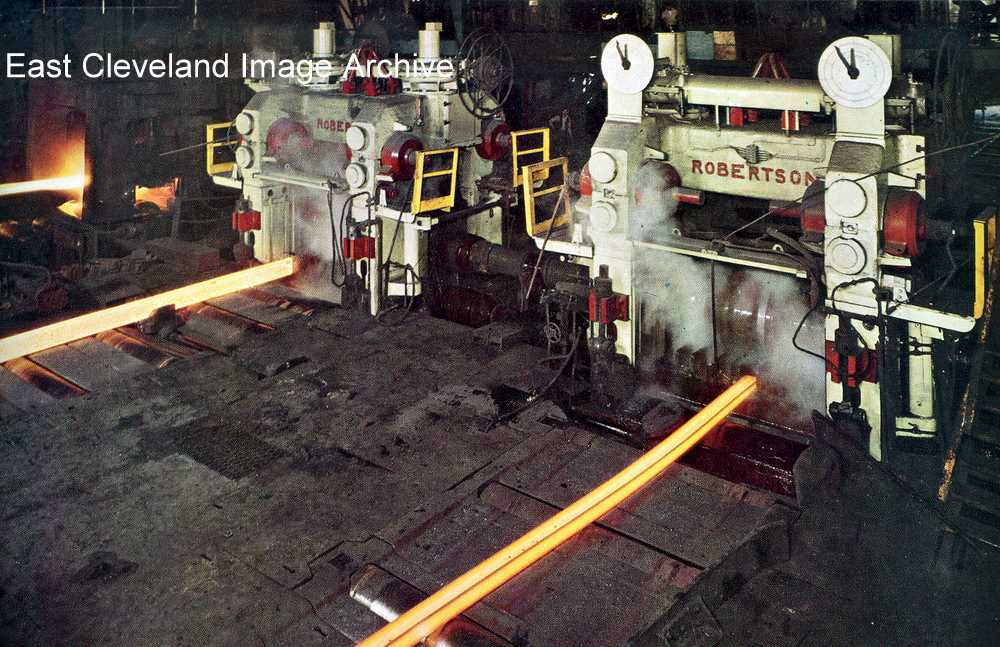

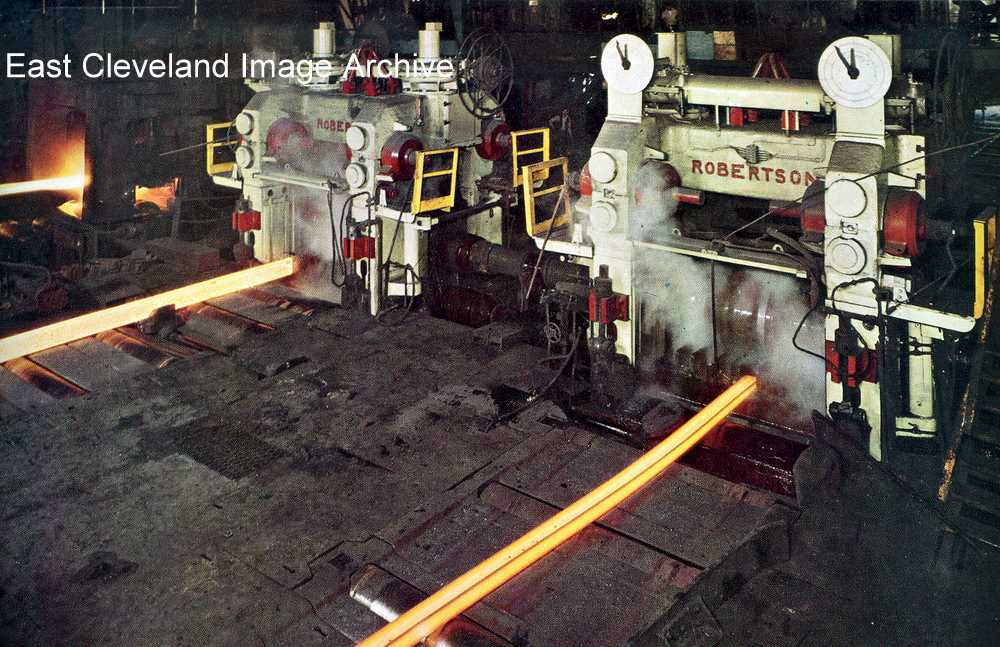

This image of the 36 inch Mill encouraged Rodney Begg to advise: “I used to spend many a happy hour on the footbridge over the output side of these two stands – trotting between the two, taking pass temperatures with a hot filament optical pyrometer when we were making 8 x 8 angles or rails – so we could prevent failure problems due to either cooling the steel too quickly or not cooling it enough. This left too open a crystal structure in the steel”.

Thanks to Rodney Begg for the update.

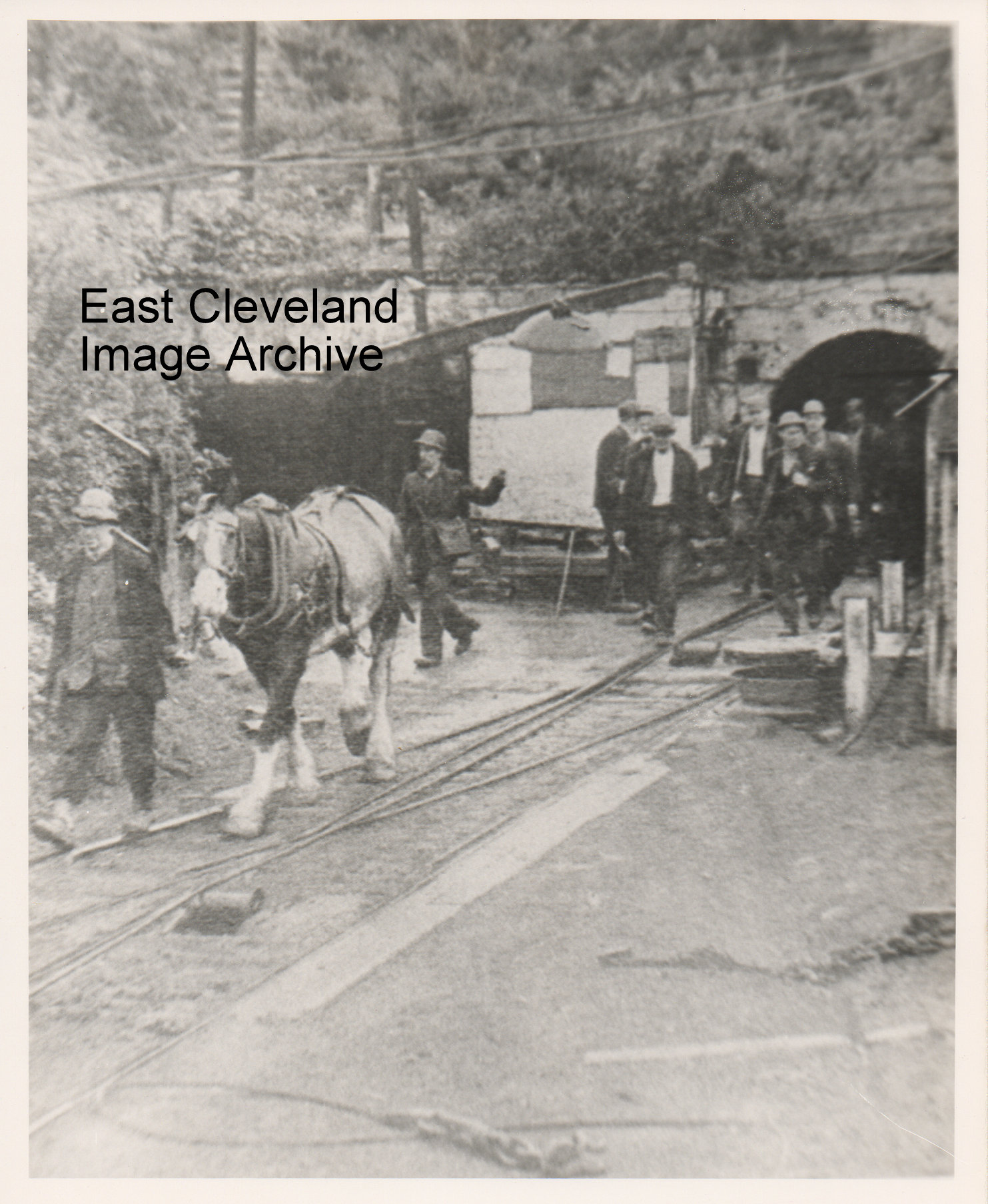

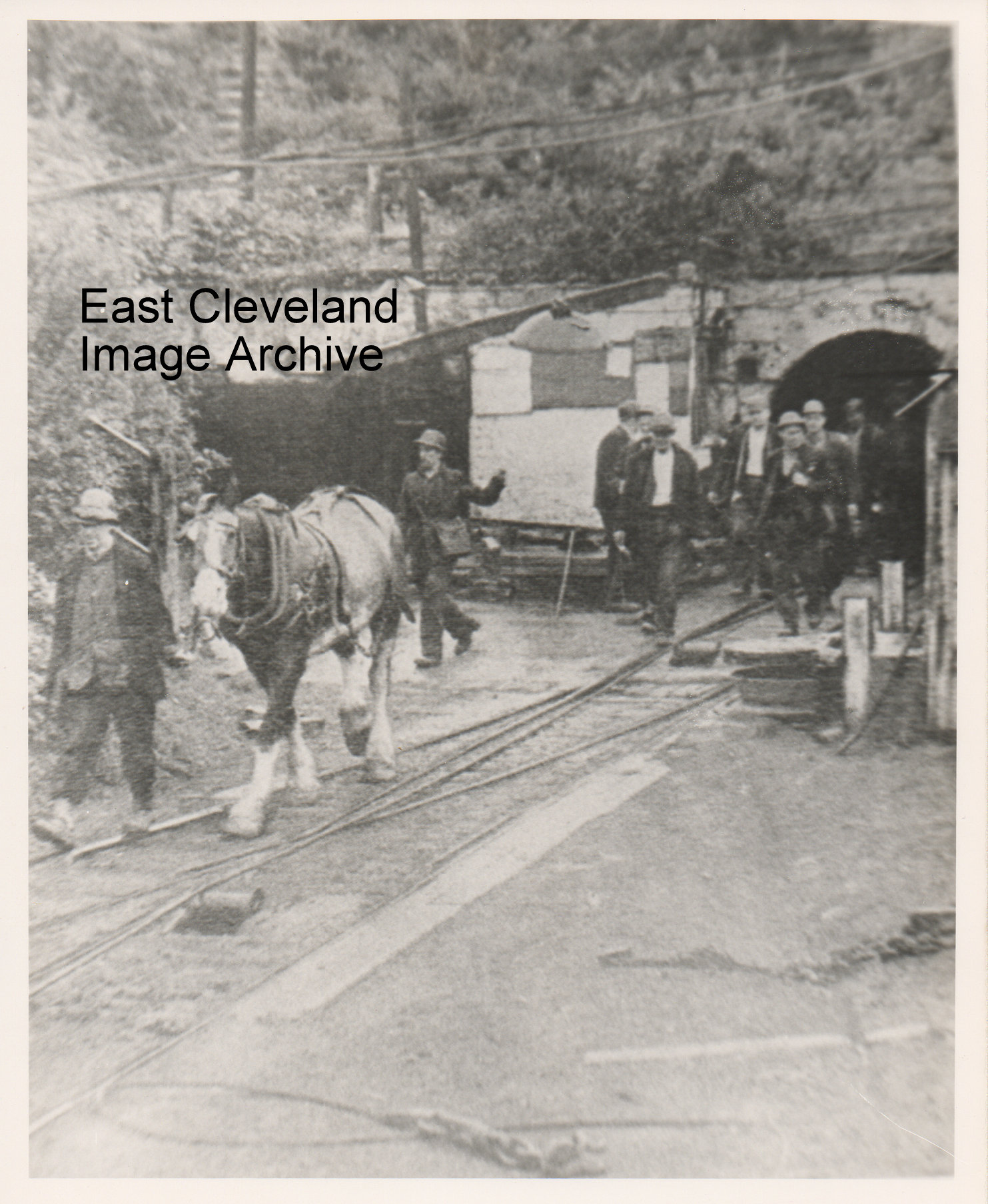

Here’s a group of miners and a pit pony (note to describe as a pony is a wrong description!) comprising the last shift coming out-bye at the Trustee Drift, Eston Mine, 18th September 1949. The mine had worked its 99 year lease, to the day. You can see the pulleys, rollers and cables of the main and tail haulage system for moving the setts around.

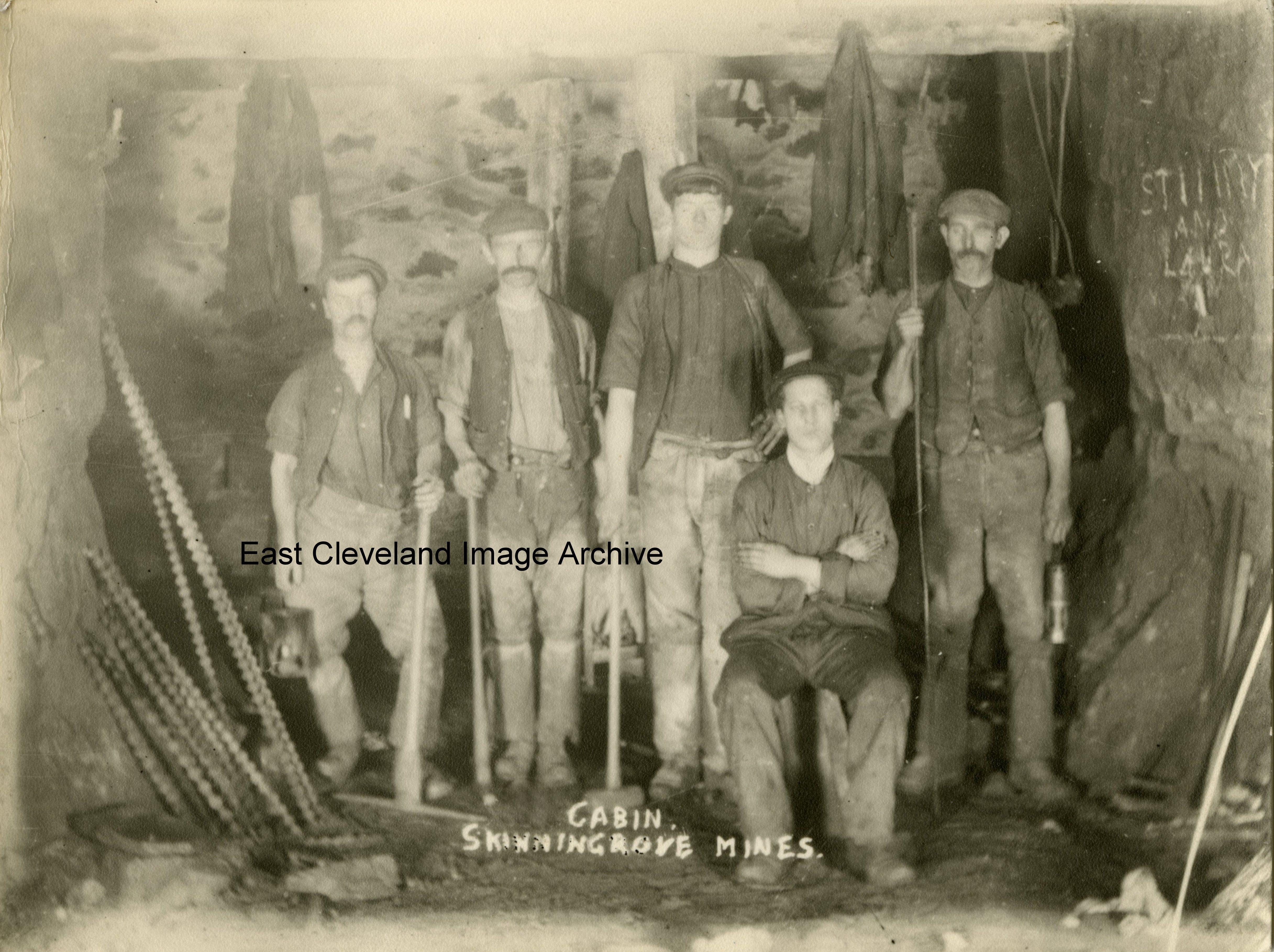

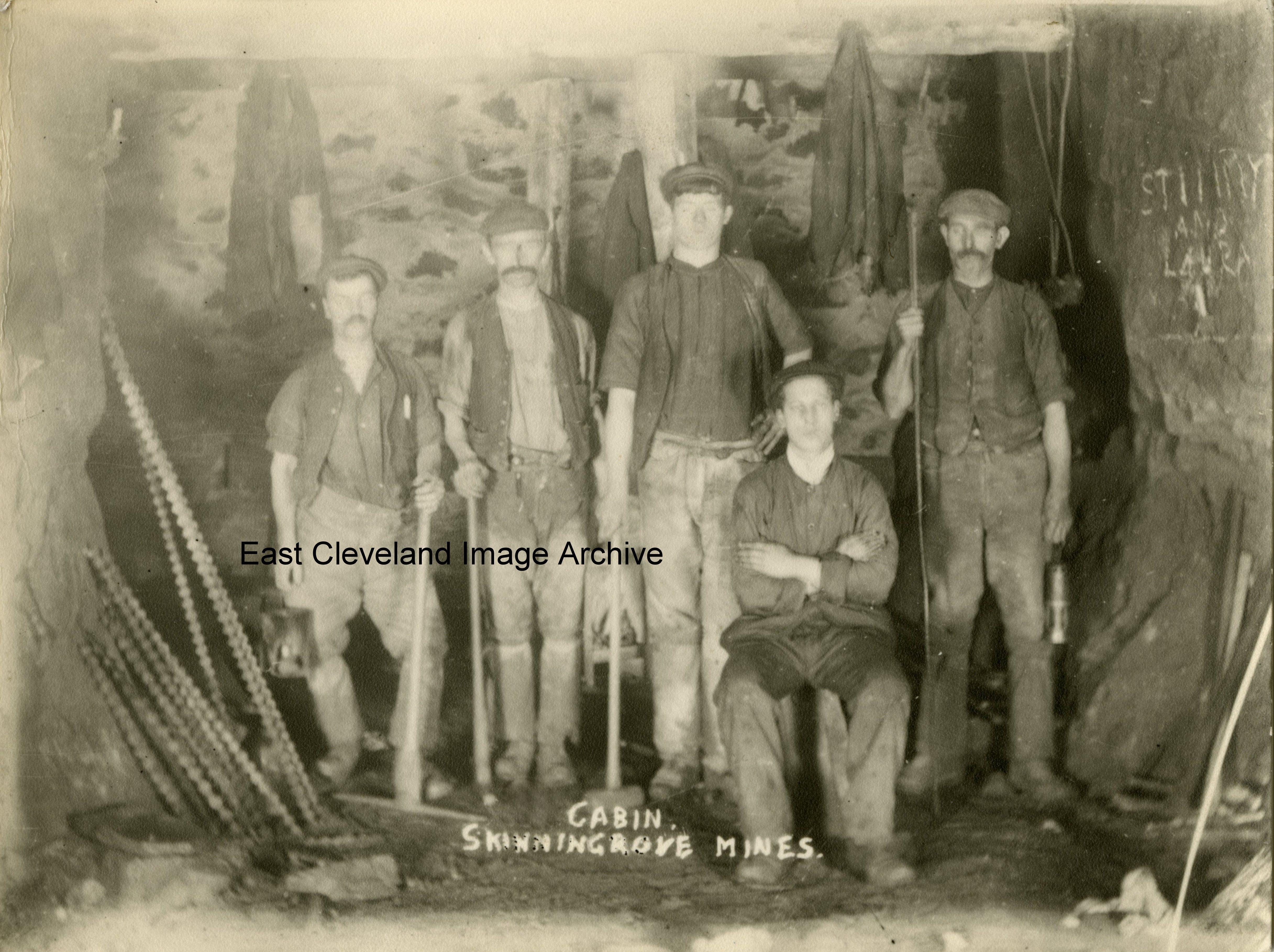

An ‘at work’ view of a group of miners – the lighting is obviously from magnesium flash placed at ground level. Now known to be a postcard dated 1910 and sent from Micklow Terrace in Loftus. It is a view of the ‘Deputies Cabin’ at Loftus Mine; Deputies were in charge of a District (specific mining area of an ironstone mine). Notice the conventional midge on the left and the Davy safety lamp of the Deputy on the right (holding the roof probe); also the rack of drill bits leaning against the wall on the left. Can anybody provide names?

Image courtesy of Jean Hall and Olive Bennett.

An image of Loftus Railway Station, unfortunately a little age-bleached, but showing the beautiful Victorian canopy well.

Image courtesy of Pauline Dolling.

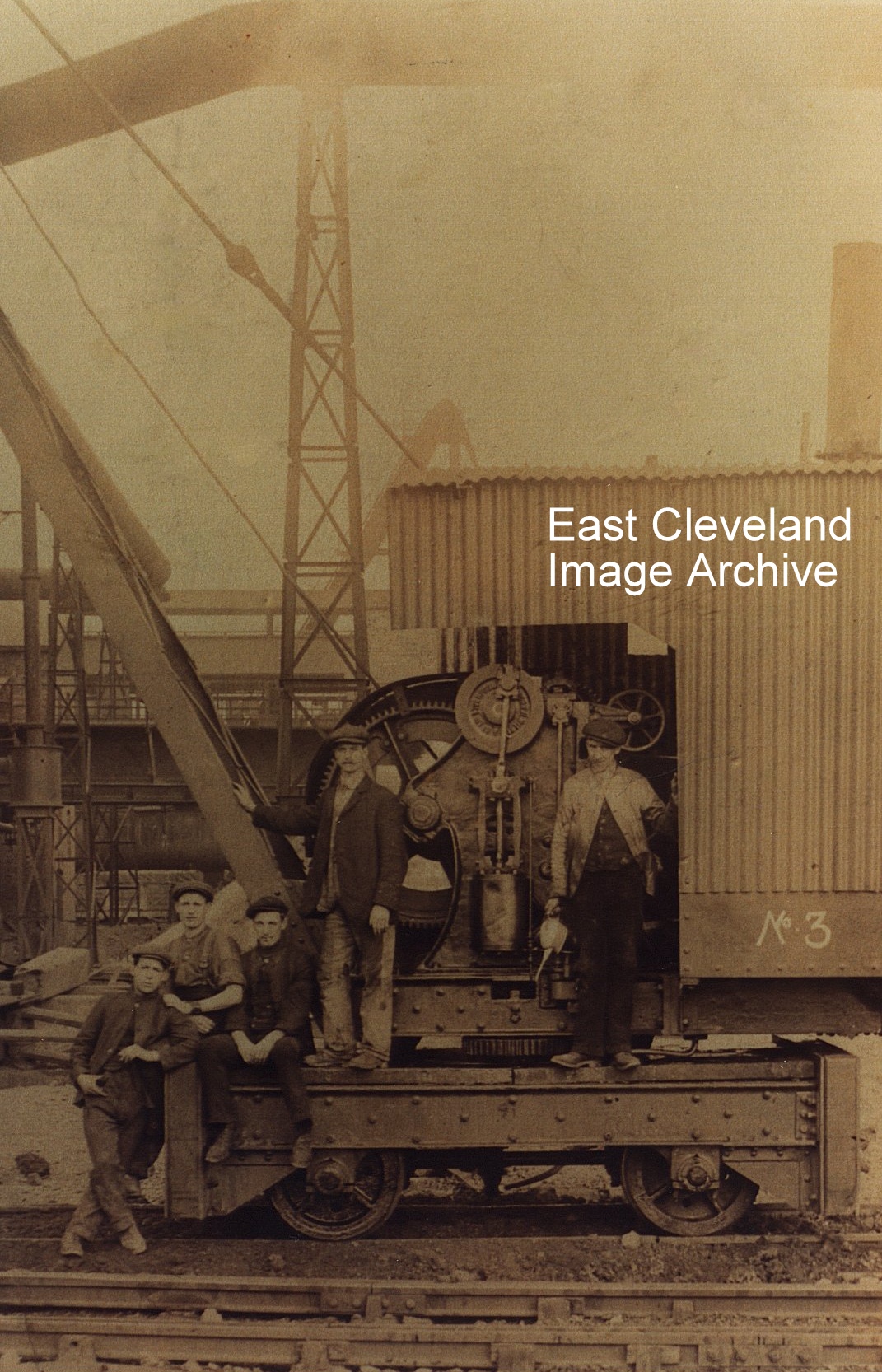

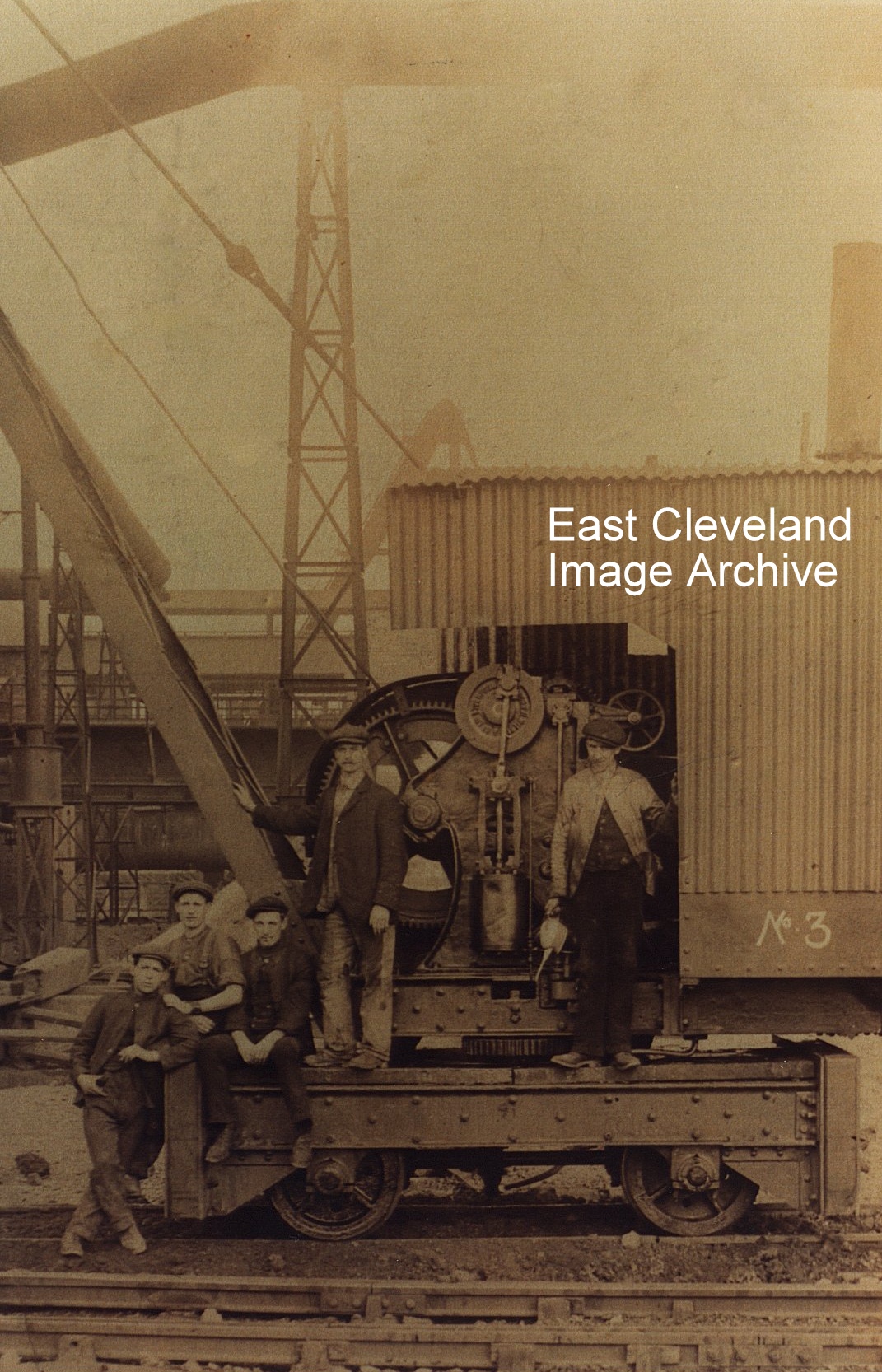

Once again the Archive asked ”Who were these men and what date was this photograph taken?” Terry Clarke t0ld us: ”I remember that crane it was called the Goliath.” George Brown told us: ”This photograph is in the book ‘Skinningrove Iron and Steel Works’ by Cliff Shepherd; it was no. 3 crane, constructed by J. H. Wilson and Co. of Liverpool. The smallest crane at Skinningrove at that time, the photograph was courtesy of the East Cleveland Image Archive”. Whilst Terry Robinson tells us: ”No. 3 three-ton steam crane. I remember as an apprentice fitter, being allowed to drive this crane from the fitting shop back to the old loco shed just before finishing time, as the regular driver Mr Ralph Walker (from East Loftus I think) knew I was interested in all things railway/steam. This was 1966/67; I finished my apprenticeship in 1969.”

Thanks to Terry Clarke, George Brown and Terry Robinson for the updates.

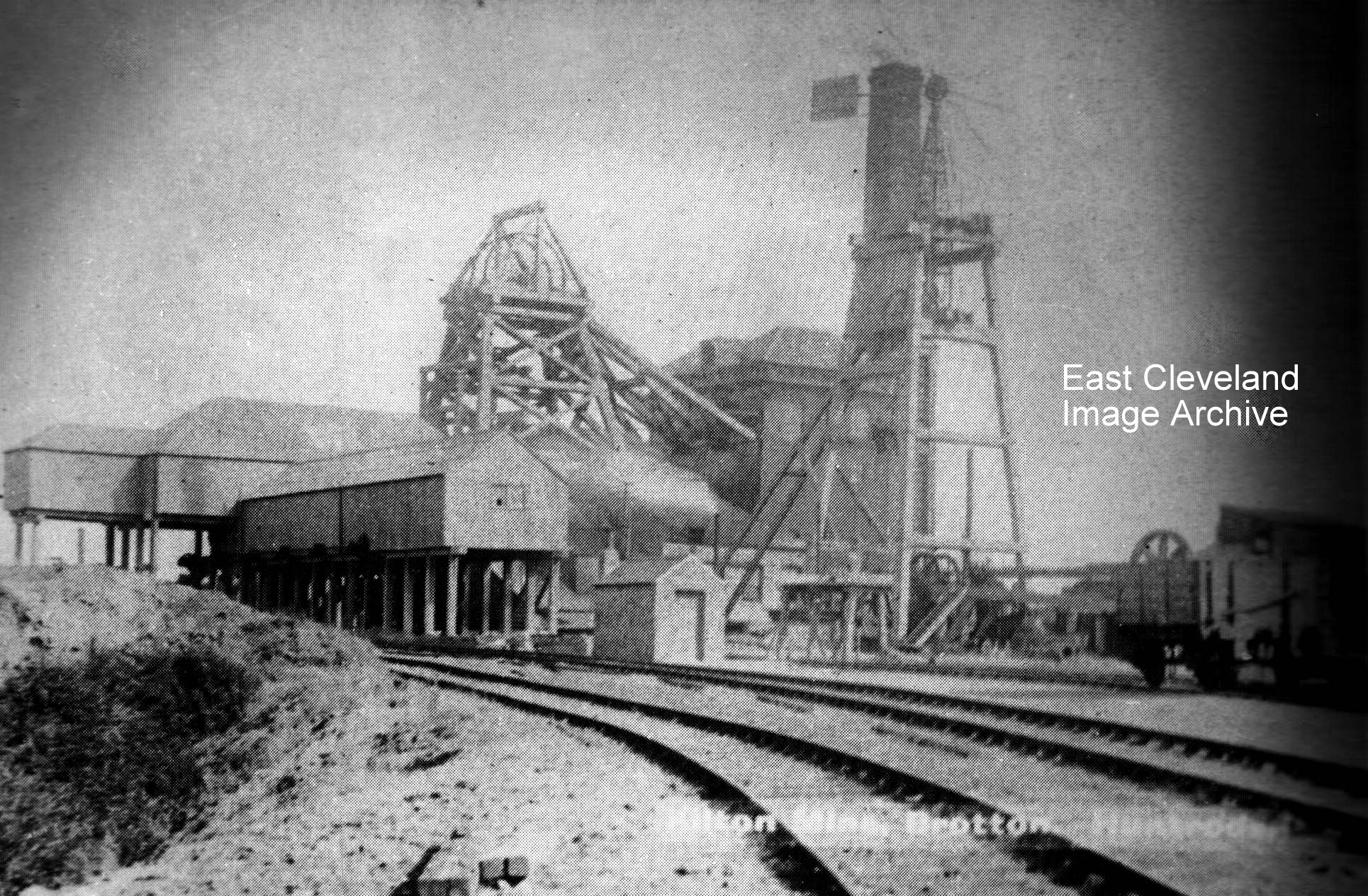

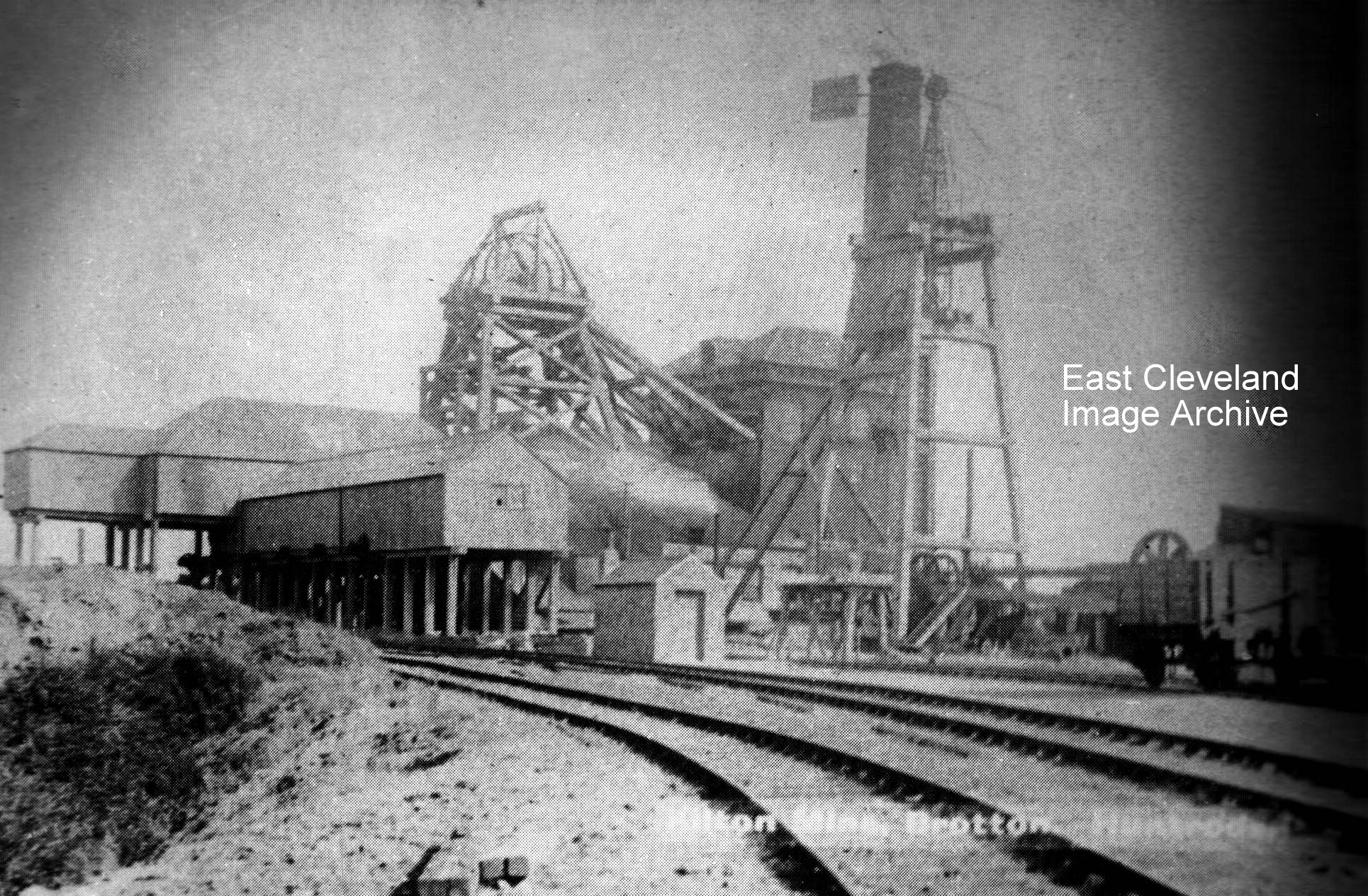

A lovely clear photograph of Kilton Pit in full production by the look of the emissions from the chimney.

Image courtesy of the Pem Holliday Collection.

The write up under the Huntrodd’s postcard view of Kilton pit included information that it was 680 feet deep and also was querying the windmill in the background possibly being used to pump water from the mine. Derick Pearson advised: “The shaft with the windmill at the back of this photograph, was an air return shaft as well as a second rout out in the event of problems. The windmill may have been used at that time to drive an output fan to draw the stale air from the workings which would in turn draw clean air in from the other shaft.”

Image courtesy of the Pem Holliday Collection, thanks to Derick Pearson for the update.

|

|

Recent Comments