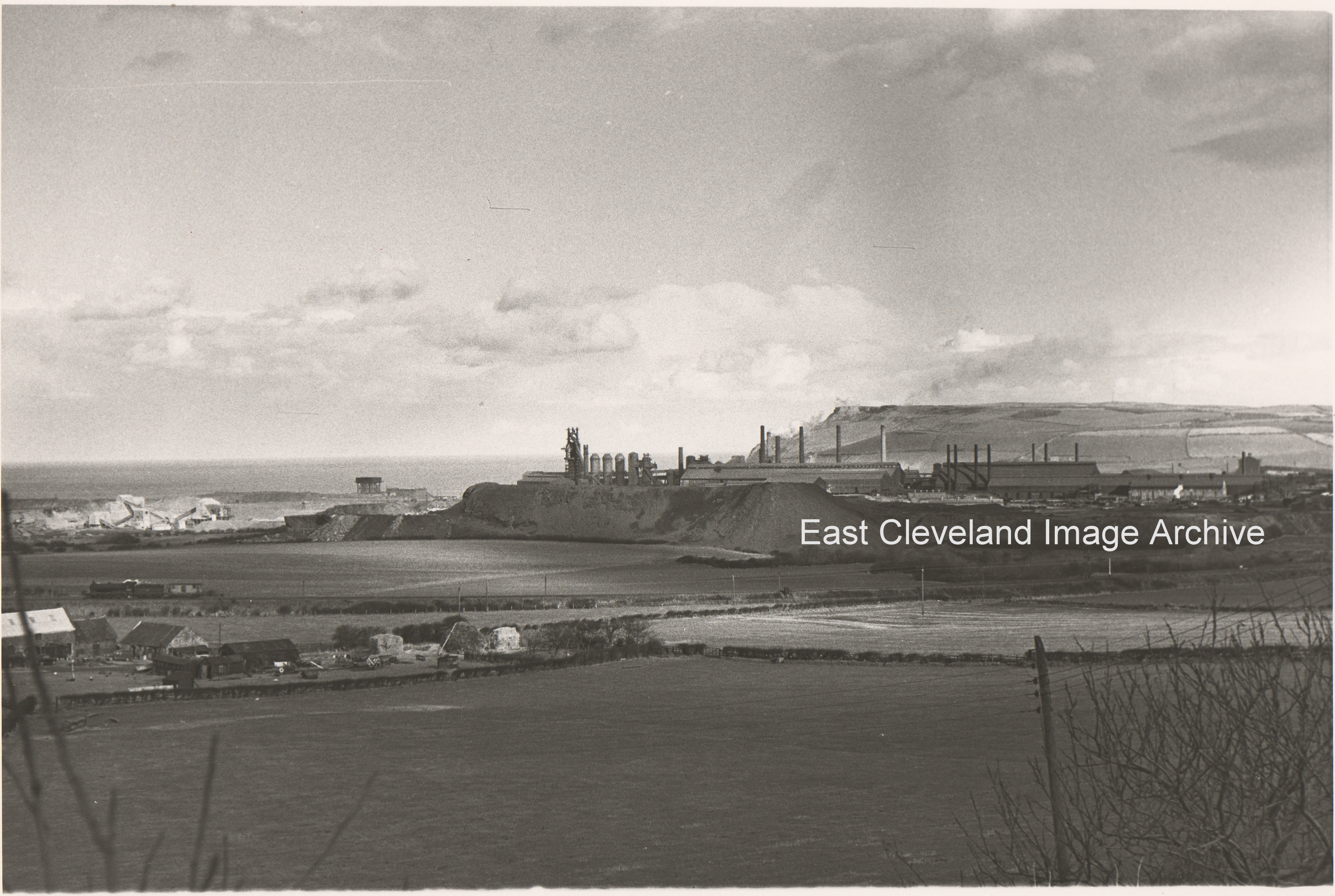

Taken from Brotton road on an autumn day with Skinningrove works in full production; dating from about early 1960’s.

|

|

||

|

Taken from Brotton road on an autumn day with Skinningrove works in full production; dating from about early 1960’s.

Taken in the late 1950’s this photograph shows none of that characteristic staining from the sinter dust. Commissioned in 1957, built by Head Wrightson and the Sinter Plant stood on the site of the old coke works and blast furnace range.

Here is another first, we had previously no other photographs of the foundry at Loftus. Do you have any to loan us please? Eric Johnson comments: ”An interesting view of the cupola melting furnace at the foundry, apparently being demolished. Three men are on the charging platform, the charging door on the cupola is open where the charge of pig iron/coke/limestone was introduced. To the right is a hoist on a large beam (above the standing men), used to raise the charges to the platform. At the base of the cupola the air chest for the blast around the cupola can be seen, with air pipe disconnected. Standing on 4 legs, the cupola probably had a drop bottom for emptying slag etc after the days run. The foundry originally owned by Robinson Brothers who produced farm implements, ploughs, etc. They also cast drain covers and gulleys, many of which can still be seen on the streets of East Cleveland. I have seen one at Piercebridge, Co. Durham. A speciality (unique?) were the cast iron gravestones, seen in the old cemetery. Robinson Bros were regular exhibitors at the Wool Fairs in the Market Place, Loftus. Old images show many of their products and warehouse next to the present day Post Office. I believe the foundry was taken over by Tinsley & Co. and is now used by Steve Whitlock.” Bill Tinsley tells us: ”Zetland foundry was owned by my grandfather until his death in the late 1930s. My father was a mining engineer with Richard Sutcliff in Horbury near Wakefield who sold a half-share to a manager who continued to run the foundry until around 1950. I spent a lot of time there as a child with my grandfather watching and getting in the way but even as a 7 or 8 year old I learned quite a lot about casting and machining methods There was a small machine shop at the far end of the buildings.” Bill also tells us: ”The cast iron railings round Saltburn Bandstand were made by grandfather at Zetland Foundry in the mid thirties but unfortunately removed early in Second World War and melted down for the war effort. Incidentally Thomas Tinsley was apprenticed to John Wood and Co (Steam engine and winch manufacturers in Lancashire) in July 1881.The papers which I still have includes phrases “Shall not wast the goods of his masters,Shall not frequent taverns or playhouses,or contract matrimony”.The apprentiship was for “Engine Fitting”. He later went on to be chief engineer at Nostel mine nr. Wakefield before buying Zetland Foundry. I have 3 photographs taken in 1970 when I last went there,one showing a similar view with the cupula removed, but just possible to see part of the words Zetland Foundry on the hoist beam. Another showing the brass name plate (Thos Tinsley & Son) on the old office door and the third showing his house in Saltburn.” Photograph courtesy of Keith Bowers and thanks to Eric and Bill Tinsley for the updates.

A picture of Skinningrove Jetty at low tide, showing the vertical-boiler steam locomotive and a rake of pig-iron trucks, the two steam cranes and the fixed derrick crane on the end.

An image of Skinningrove Jetty with SS Hummersea moored up for loading, with two steam cranes in attendance, either just before or just after high-tide by the water levels on the jetty wall. Even more rare is the vertical-boilered railway engine (known as ”the coffee pot”) on the left with the train of pig-iron trucks; we’ve never seen an image with these on before, or with a vertical-boilered railway engine. The pig-iron trucks were lowered from (and raised to) the works via a rope incline down Jetty Bank – a feature still visible to this day. SS Hummersea looks pristine – we wonder if this was her first trip? Her last according to the Commonwealth War Graves Commission was during World War I, when it was believed she struck a mine and sank. Charles Hannaford advises us: ”My great uncle, Charles F Hannaford, was the Master of the S.S.Hummersea. The ship was lost in December 1915, probably by an enemy mine as my uncle died from his wounds in naval hospital, London on 30th December 1915 and listed as a casualty of war. As the wounds were unlikely to have been caused through the ship foundering in the bad weather and the submarine activity at the time was low, a mine is the most logical explanation.” Many thanks to Charles Hannaford and Terry Shaw for the updates.

Seen here, the SS Northgate at Skinningrove jetty with the cranes busy at her side. The details that follow are from the ‘Tyne Built Ships List’: Name: NORTHGATE |

||

Recent Comments