Roof bolting supports at main road junction.

Image courtesy George Pearson.

|

|

||

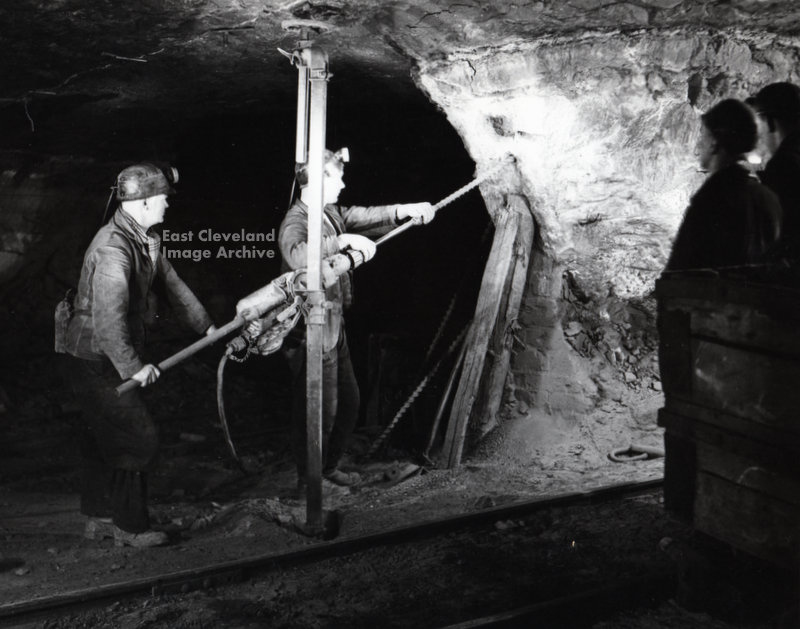

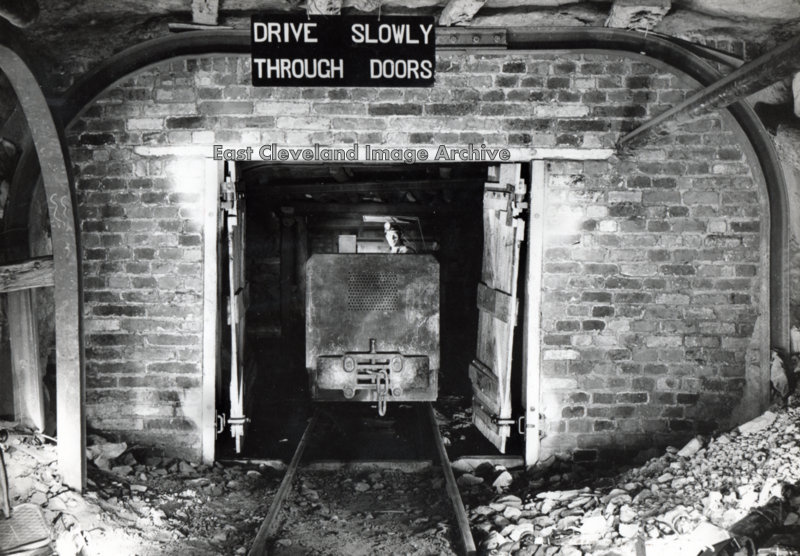

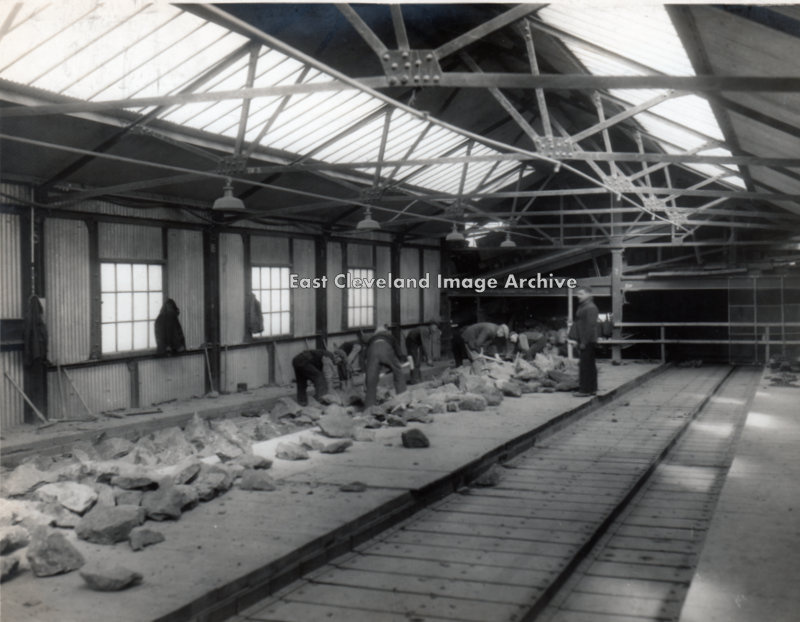

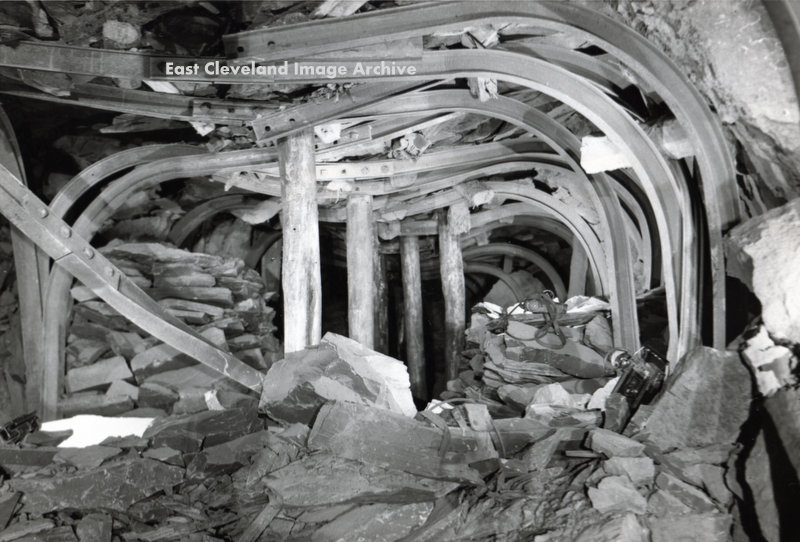

Roof bolting supports at main road junction. Image courtesy George Pearson.  Miners using a pneumatic powered post drill at a junction, in Lingdale Mine 1950s. Image courtesy of George Pearson.  Self closing ventilation doors held open at Lingdale mine, this was needed to help direct the flow of air around the workings, dated 20th November 1958. Image courtesy of George Pearson.  A typical scene on the picking belt at an ironstone mine in Cleveland. Here the shale was seperated from the ironstone as it came from the mine, larger lumps are being broken up by sledge hammers. Bill Danby tells us: ”My brother in law, Frank Holmes, who was a Deputy at both Lingdale and North Skelton Ironstone Mines says that this photograph is most likely Lingdale. North Skelton did not have a “belt”, as there so little shale content in the ore extracted from that mine, whereas at Lingdale the shale content was high. Hence the man-made mountain that used to stand behind Coral Street. South Skelton Mine, he adds, also had a “belt” but it was on a slope.” Image courtesy of George Pearson and many thanks to Bill Danby (and Frank Holmes) for the update.  Underground at Lingdale; viewed from the tub end, of a ”Cranner”, about to tip the stone into the tub. Image courtesy George Pearson.  An excellent view; dating from November 1958 of a loaderman and his Eimco Mechanical Machine called a “Cranner” in Cleveland. The bucket picks up the stone and tips it into the tub behind the Cranner. Image courtesy of George Pearson.  The effects of a roof fall in Lingdale Mine; the bent and twisted steel mine arches, are evident. The use of wooden pit props seem to be used to stabilise the roof. Image courtesy George Pearson.  A good image of the engine house at Lingdale mine. The round brick kiln on the right was part of an attempt to make the mine profitable, using shale from the tip (especially during slack times). It wasn’t particularly successful, but probably contributed enough to prevent total closure of the mine. Lingdale mine was one of the deepest mines in the Cleveland system and also had the poorest yield, there being a large band of shale splitting the seam in two. This resulted in the huge shale heap which took forever to dispose of! Lingdale village was described as almost derelict in the late Victorian era, the difficulty of winning the stone meaning that the mine was closed more often than in production. Image courtesy of Maurice Grayson.  Albert Dobson of Carney Street, Boosbeck; Gus Coote and Clarence ‘Clarry’ Ditchburn of Moorsholm leading out the mine horses on August 28th 1959. Because of the height of the ironstone seams, horses as opposed to ponies were employed in the Cleveland District . These details confirmed by Ann Jackson: “Clary or Clarence Ditchburn was my Dads cousin and lived at Moorsholm. His Mother was Elizabeth Ditchurn nee Shaw.” and Janice Walker: “Clarence was my uncle ,he was married to Mary.My dad was Reginald Ditchburn he left Moorsholm to live with his sister Eva May Stanforth in Leeds.” Image courtesy of Maurice Grayson, with updated information courtesy of Alison Small and Lingdale History (Communigate). Thanks also to Ann Jackson and Janice Walker for the updates.

Well the photograph is dated and tells us what is happening so there is no more for me to write. However Derick Pearson tells us: ” I was standing on what was the footings of Coral Street and North Terrace at Lingdale; I took this for the records of Lingdale local history at that time. The shale heap was being removed by George Carey Haulage. The man on the D6 digger and loading the lorries was George Found and the man in the lorry that day was George (Sooty) Thorpe. The bungalow you see was my father-in-laws and the red Volkswagen Caravanette on the driveway was mine.” Photo originally taken by Derick Pearson and many thanks to Derick for that update. |

||

Recent Comments