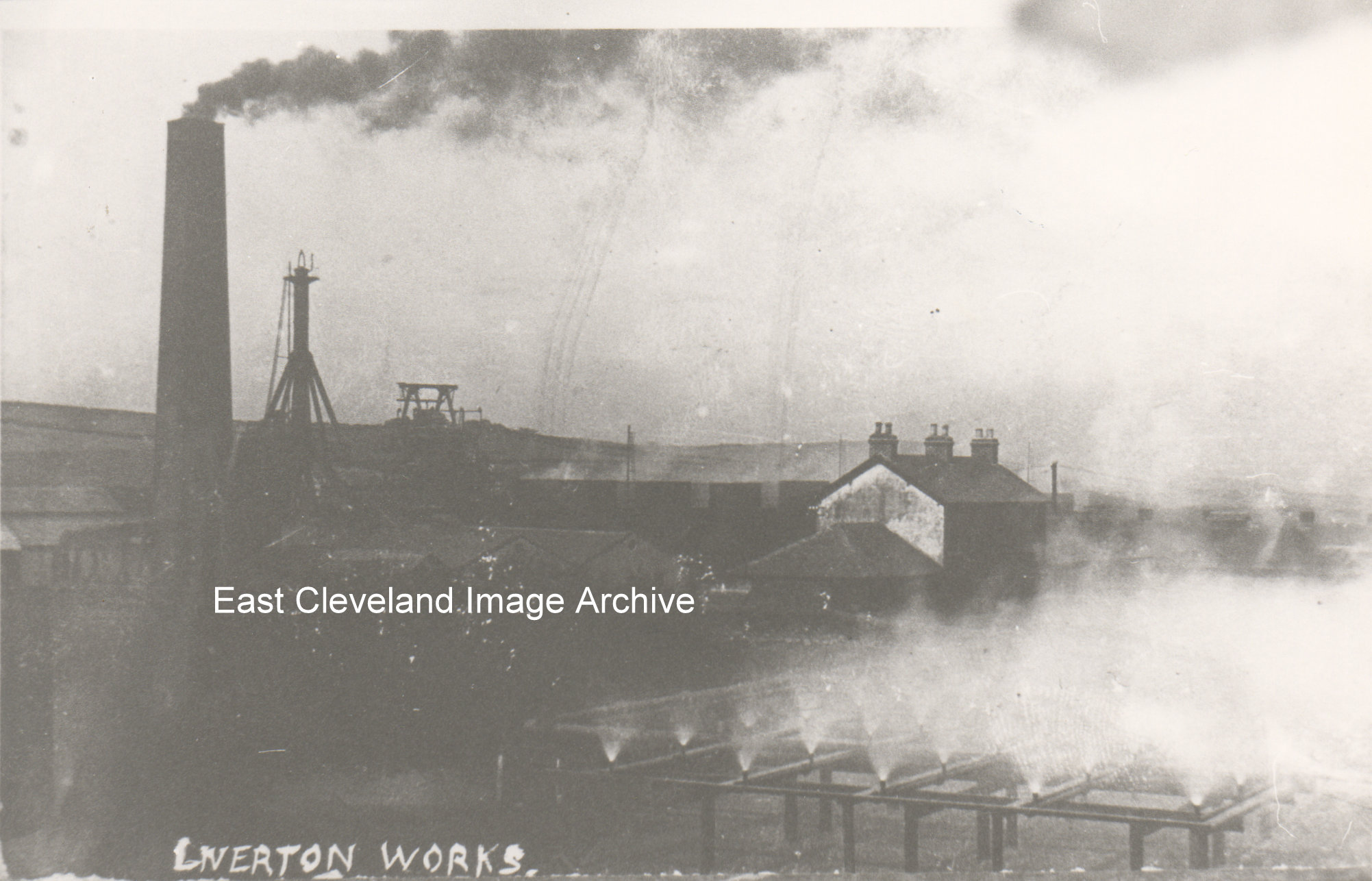

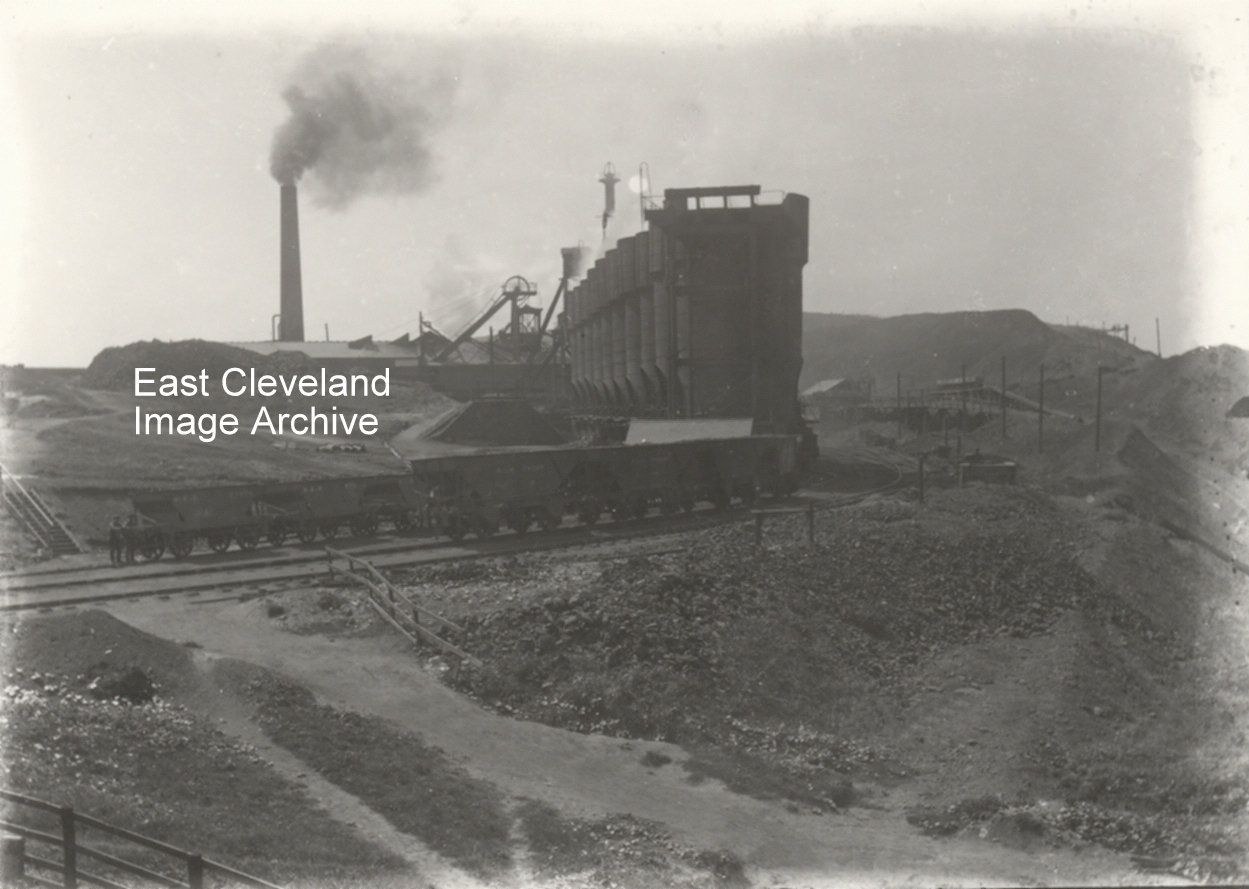

Liverton works, with the spray bars in the right-foreground, this was actually part of the Liverton ironstone mine. Graham Suggett asked: “My grandfather worked at the Liverton Mines pit until it closed, he was winding engine foreman. He lived at Graham Street (note my given name). He kept ducks on the reservoir. Presumably the reservoir fed the spray bars. Please, what were the spray bars used for?” Simon Chapman advised: ”The water spray in the reservoir did two things: it was the exhaust steam from the engines so it was condensed back to water which also warmed up the water in the reservoir before it was pumped into the boilers. This was part of an extensive modernisation scheme at the mine about 1903 to make the place more efficient” Graham also added: “How ingenious and energy conscious those miners were. My grandfather, Harry Brown, operated the hoist until the mine closed and he retired.”

Image courtesy of the Pem Holliday Collection and others; also thanks to Graham Suggett and to Simon Chapman for the updates.

Recent Comments