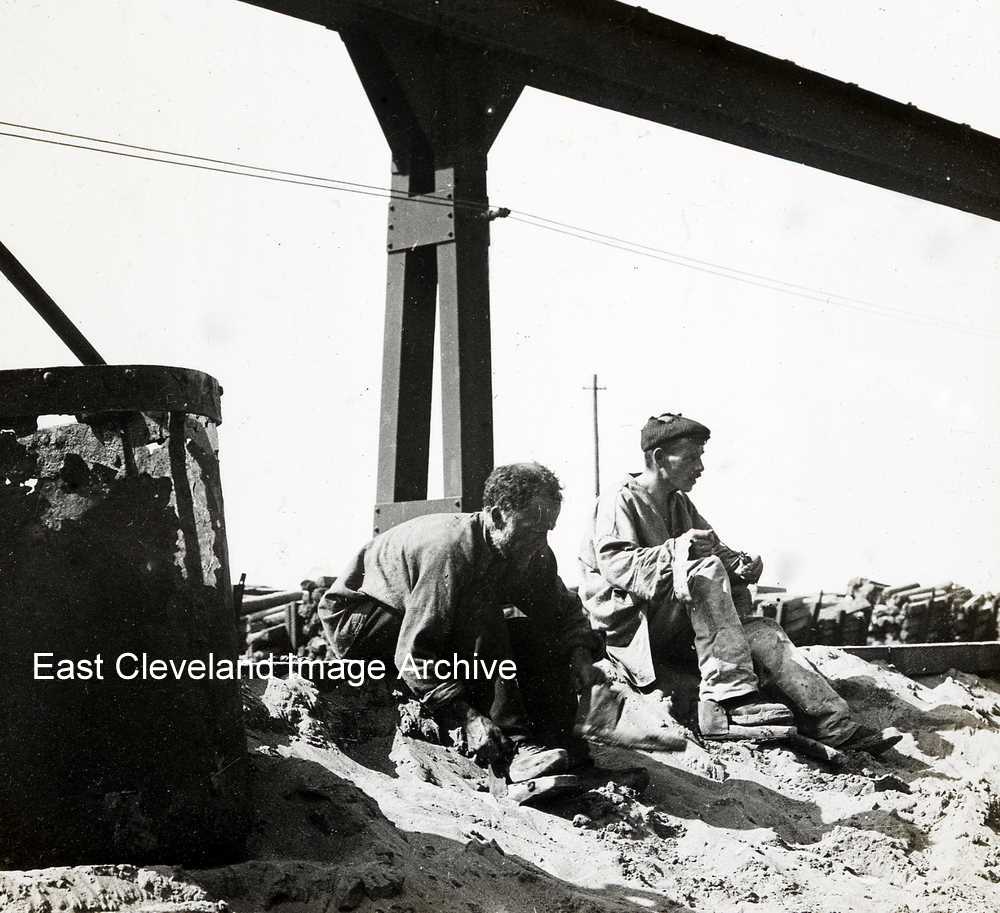

This image (pre-1950) shows the left-hand man strapping on his clogs – shaped wooden soles to protect his rocker boots from the heat – before going in to do some hot work on the casting floor.

|

|

||

|

This image (pre-1950) shows the left-hand man strapping on his clogs – shaped wooden soles to protect his rocker boots from the heat – before going in to do some hot work on the casting floor.

An image of a stack of pigs being stock-piled. The bar in the labourer’s hand is to break the pigs off the sow.

When the furnace has cast, the pigs are attached to the sow and the crew have to go around and break them off and heap them together in slings to be stock-piled.

Well…not quite. The tip labourer is spragging the wheel of the slag Bogie prior to tipping the slag over Cattersty Cliffs.They were tipped by using a chain and winch system through the hook on the side of the pots (on the other side of ladle). You can just see the chain hanging below the pot, to the left of the labourer. The Loco is one of the Low height types used on the Blast Furnaces. It certainly cast a lovely glow over the scene at night! Image courtesy of Dave McGill (a glass plate negative).

A pig bed with the gate irons in place ready to divert the flow of metal to fill the pigs.

These two men are preparing the sand runners (sows) and moulds (pigs) to receive the molten metal from the blast furnace.

The aerial ropeway which transported ironstone from North Loftus (Skinningrove) mine. Rodney Begg remembers: “This section (without its protective screen over the road) was still in place when I started at Skinningrove – although the roadside pylon disappeared soon after – but the left-most pylon survived to become a lighting tower!”. Thanks to Rodney Begg for that memory.

This image of A furnace first tap with number 1 (75 ton crane), before the main hoist chains were changed to wire ropes. After the 8 (or 12 for the ’Big’ furnaces) hour process of turning a charge of cold and hot metals into steel, the climax usually came quickly after a flurry of samples of steel and slag to the shift lab. The hooter would sound, the bangalore torpedo (more precisely ’the shaped charge’) would blow out the tap hole and the furnace would heel over to discharge it’s first potful of molten metal. Eric Johnson told us: “The scene always reminded me of what I thought Dante’s Inferno would look like – flames up to the rafters, (sometimes bringing a flurry of pigeons down), the furnace hand on the tapping stage hurling the alloying charges of coal, niobium, ferro-manganese etc. surrounded by smoke and light and heat. The furnace tilting further and further with each potful until it was spent. The pots in their turn travelling sedately to the Ingot Shed across the way and charging rake after rake of ingot moulds with the liquid metal. Sometimes a ’flying stopper’ made it more hazardous to empty the pots as it was then impossible to stop the flow of metal between moulds and everybody in the Ingot Shed would get a scorching (if they were unlucky they’d get a lot worse!) – and, as Bob says, a wet pot could create a shower of incandescent metal dancing around the pitside”. Stan Henderson tells us: ”Awesome! Better than any fireworks display I have seen.” Thanks Eric Johnson and Stan Henderson for the updates.

This was always a beautiful sight to behold – a portable spout was placed into the gaping door (usually an end one) of the furnace and with its siren whooping the crane would manouevre the sizzling pot of iron over it, then delicately empty the pot into the furnace – bringing memories of bonfire night! Eric Johnson told us: “The chap in the foreground with his back towards the camera is Sid Carter, also note the sample pot”. Rodney Begg has advised: “I think this must have been taken on my shift (’C’ shift I think it was ), because I recognise the first hand with his back to the camera, he used to let me fettle for him as ’acting-temporary-fifth hand’! We were kept us busy around tapping time (taking a sample) and the sample lad ( a Theaker from Boosbeck, I think) used to curse if the sample was over-quenched and wouldn’t drill! Sid was always impatient – he would wait in the balance room/bait room pacing up an down while Stan (or Derek, the 2nd Chemist) did the analysis – as a lowly 3rd Chemist I was only allowed to do slags and iron samples!”. Thanks to Eric Johnson and Rodney Begg for the updates.

Rodney Begg tells us of de-siliconizing: “When I was at Skinningrove this had fallen out of favour and the equipment lay at the end of the Talbot’s, next to ’D’ furnace. Sound in principle and obviously successful in other areas (this is the basis for Basic Oxygen Steelmaking), it never seemed to catch on at Skinningrove!”. Thanks to Rodney Begg for this observation. |

||

Recent Comments