|

|

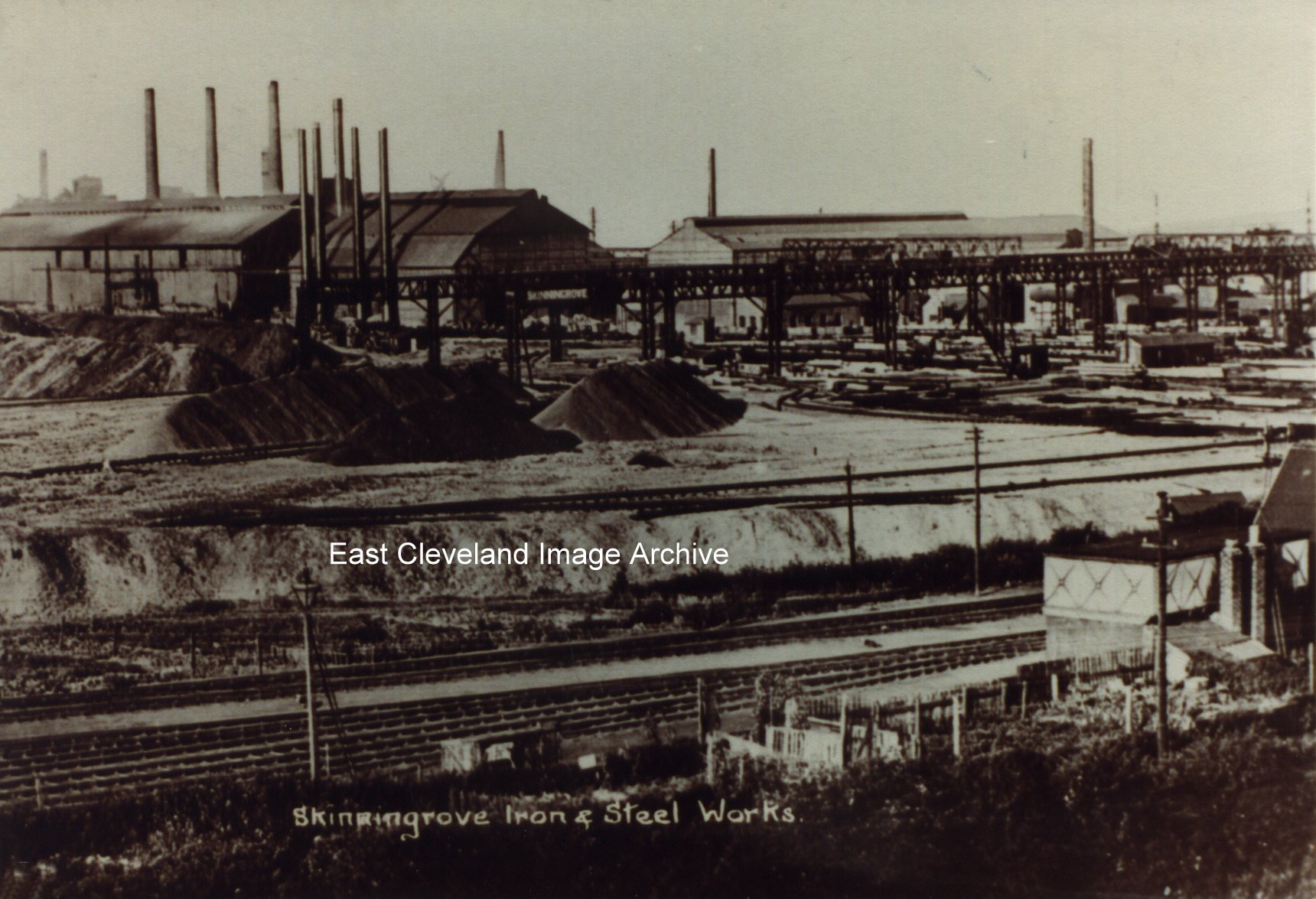

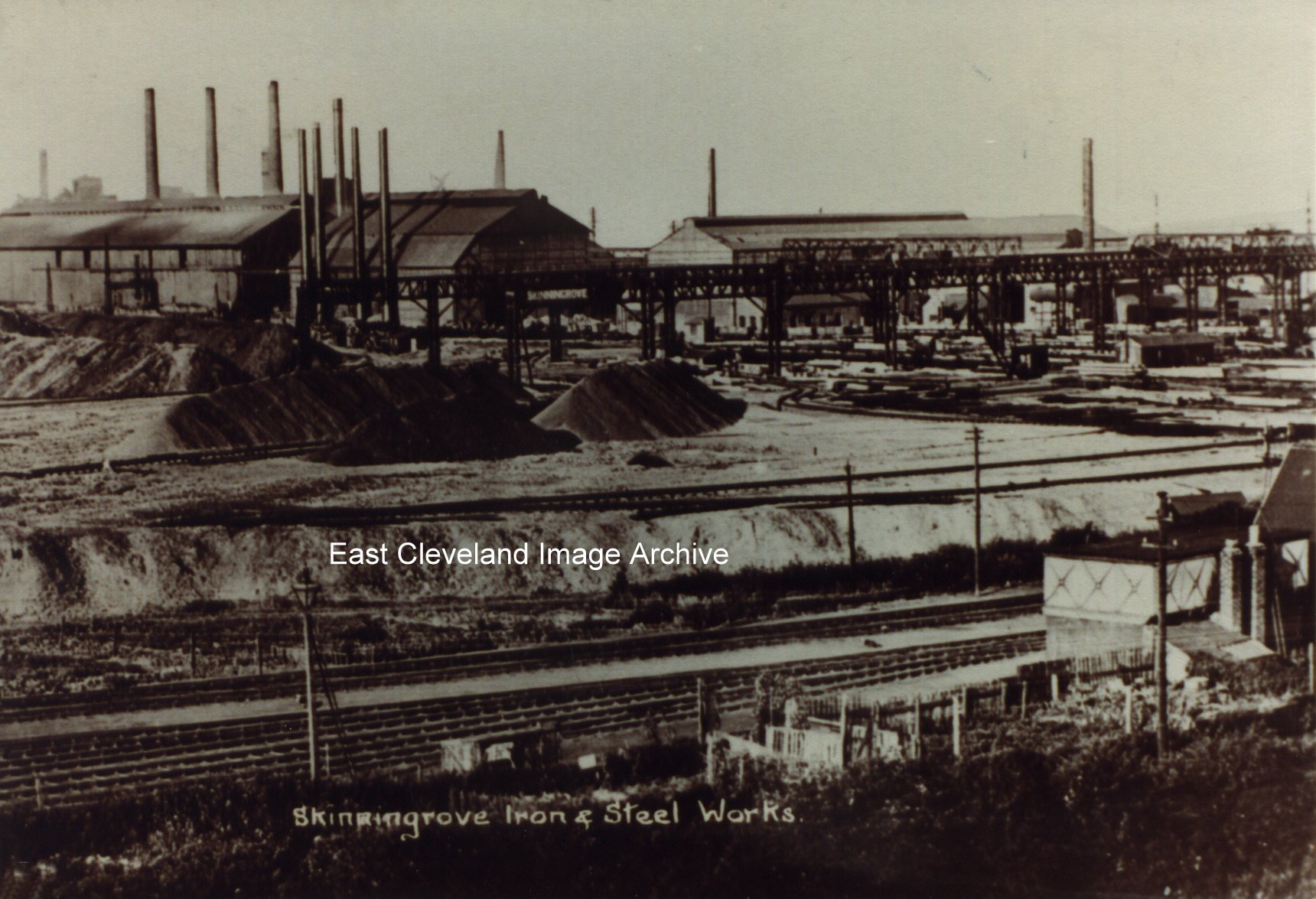

Skinningrove Iron and Steel Works is a postcard image by George Skilbeck, the view is from Carlin How towards the Talbot’s, the Scottish Agricultural Slag plant is off to the left; you can just see the basic slag heap from the Talbot furnaces. The railway station is in the right foreground with the locomotive water tower just in view and the stockyards are mid-right of the image. David Mills asked: “Hi I wonder if you could help me I’m looking for some information regarding the demolition of the steel plant at Skinningrove in particular which company demolished the plant? My father worked for a company called F. B. Parvin Ltd; I believe it started to be demolished around the end of 1972 into 1973.” Can anybody assist with information?

Image courtesy of John G. Hannah and thanks to David Mills for the update.

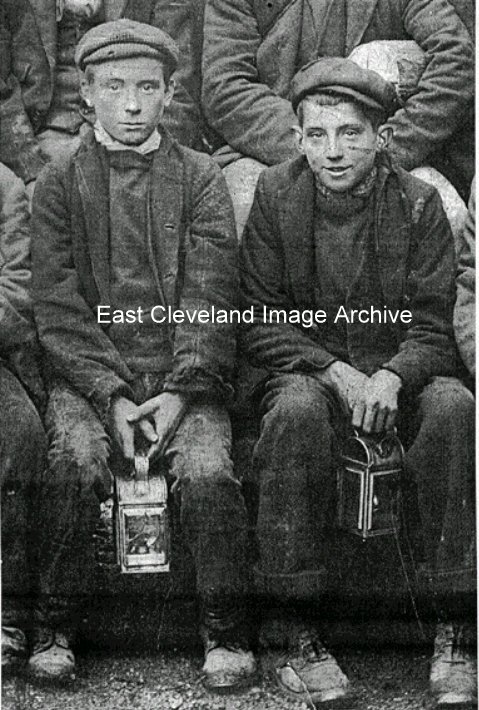

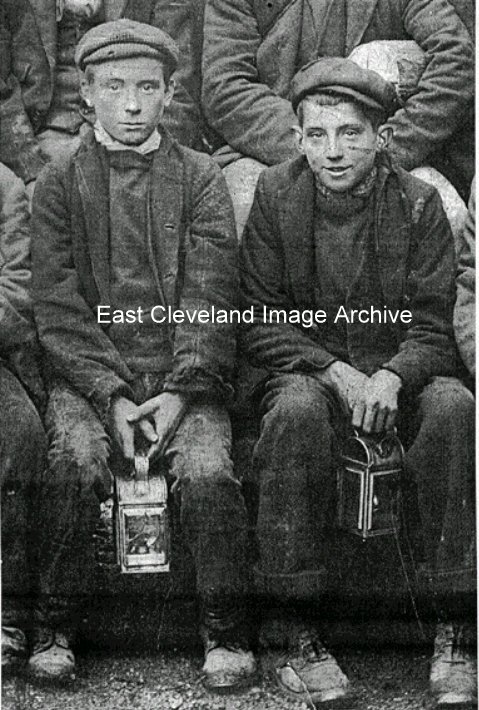

Now known to be part of the workforce of the Boulby and Grinkle mines, Trappy Lads were present in all mines. This was the job you got when you left school in the pit villages of the North-East – these lads look about 14 – their job was to open and close the ventilation doors as the horses and tubs came through. They’re possibly wearing ”miner’s heels” which were an attachment to the workers boots of the time – you knew you’d been kicked if you got a ding from these! – the lads are carrying Tinplate ”midges” by the look of them, they used candles in the earlier days, later carbide powered midges were used. Part of a larger group image, which can be viewed later in the Archive.

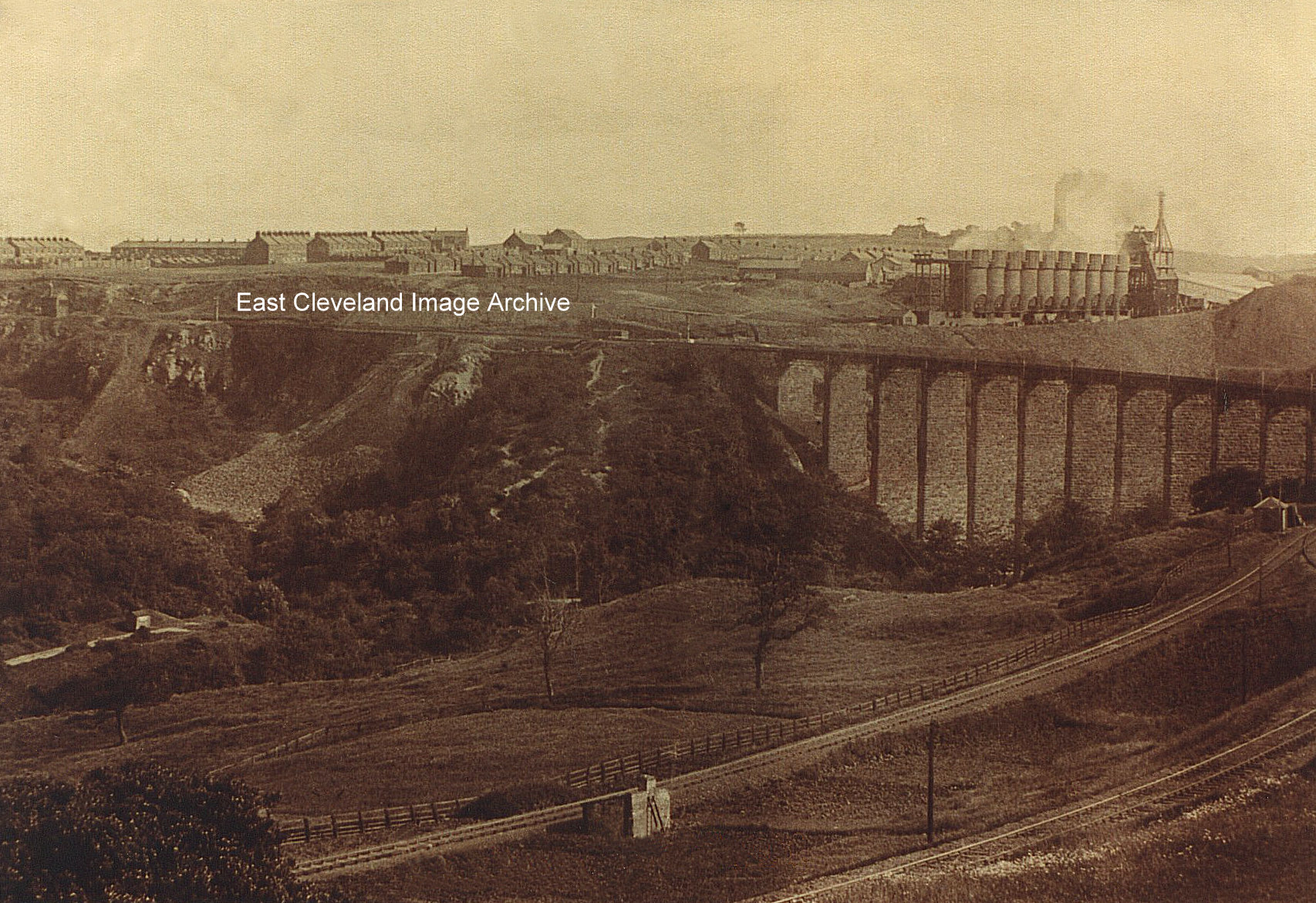

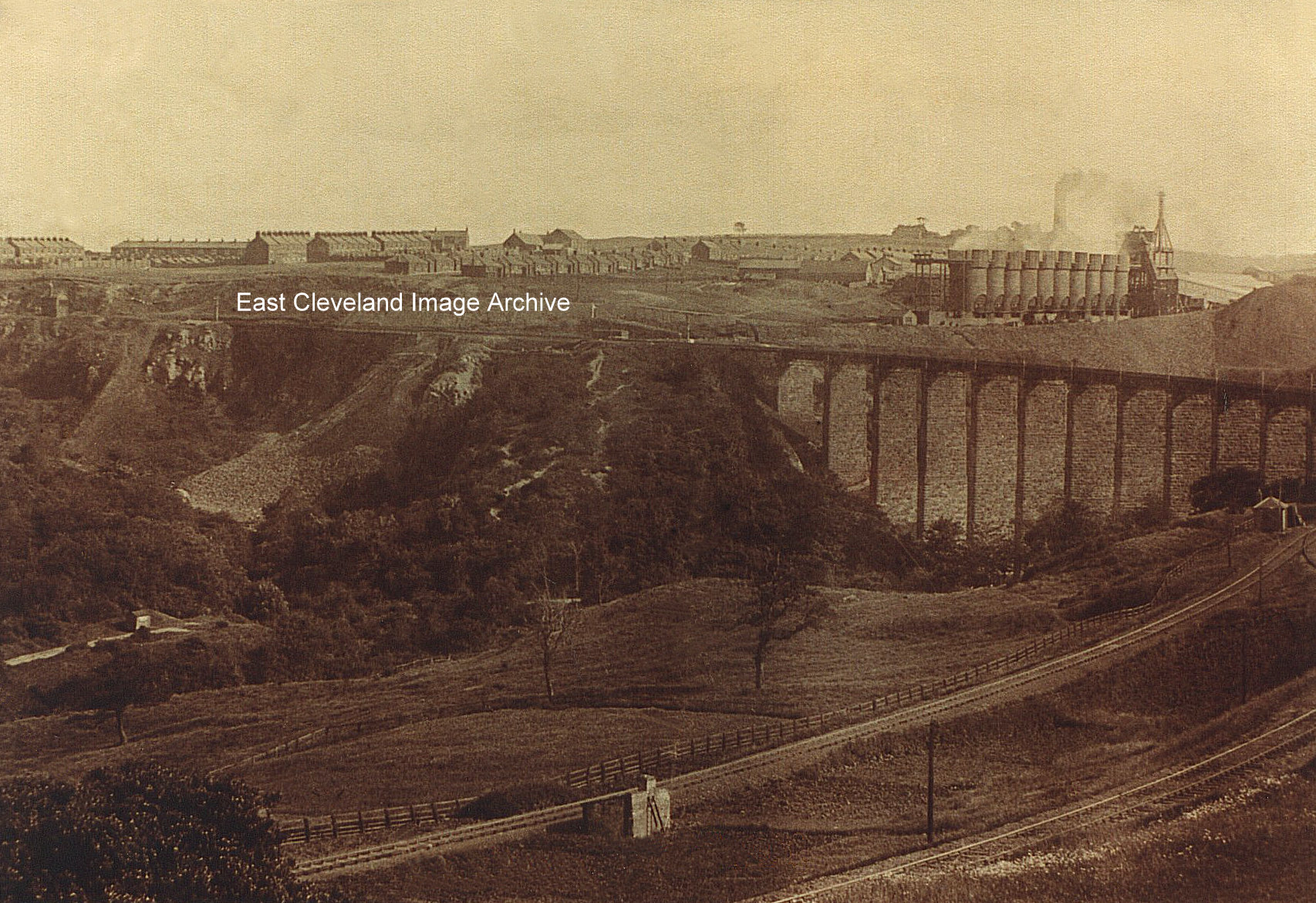

A view of Kilton Viaduct (prior to filling-in) to create the embankment of more recent times with – New London – being the planned name for the present day community 0f Liverton Mines when investors took on the venture. The investors had even suggested a variation in the name to Little London if they could get aggrement of the locals. The long sweep of the viaduct is easily visible in this image, as are the calcining kilns at Liverton Mine; the fumes from which used to rot the clothes of the labourers working on them. Norman Patton says ”Our family moved from “Brickyard” to Liverton mines in 1952. The promise of a fitted bathroom and hot and cold running water; with a garden front and back was too much to resist! Wages at Kilton pit were good at the time and the journey on push-bike much easier for our father. We even had a television before the Coronation and the Stanley Matthews Cup Final (12” Black and White, Console model no less)”. The new estate of council houses inspired the name ” New London” for the village and the council estate was the “Holy City”. ”Brickyard” being the local name for the Hartington Street, High Row and St Hilda’s Terrace area of Loftus; similar epithets applied in Brotton and elsewhere in Cleveland.

Thanks to Norman Patton and Derick Pearson for additional information.

All through the life of the mines there was a constant battle to increase yield without increasing manpower. Ironstone was won by blasting a portion of the rock face out and then loading the stone into a tub (or sett) to be taken back to the heapstead. To place the shot the miner had to create a hole into which he could place his powder, detonator and fuse. This was the time-consuming part of the job initially carried out by hand; then by hand ratchet drill; then by either compressed air, petrol or electric drill. This obviously posed photograph is a record of the testing of just one such drill. This picture and the other one entitled similarly are two out of a group of four pictures taken about 1900 when Whitecliffe Mine was re-opened and this compressed-air drill was tried out underground. From the earliest times the hand ‘jumper’ drill was used, in 1875 the first compressed-air powered rotary drill was invented. Loftus Mines introduced such drills in 1891 but they were big and cumbersome so this one illustrated was tested but never adopted.

Later electric drills were used in Loftus but about 1895 hand-operated rotary drills were introduced (the so-called ‘ratchet’) and eventually superseded the powered drills. Loftus Mines, however, were never as mechanised as the Dorman Long mines in Cleveland. (words by Simon Chapman).

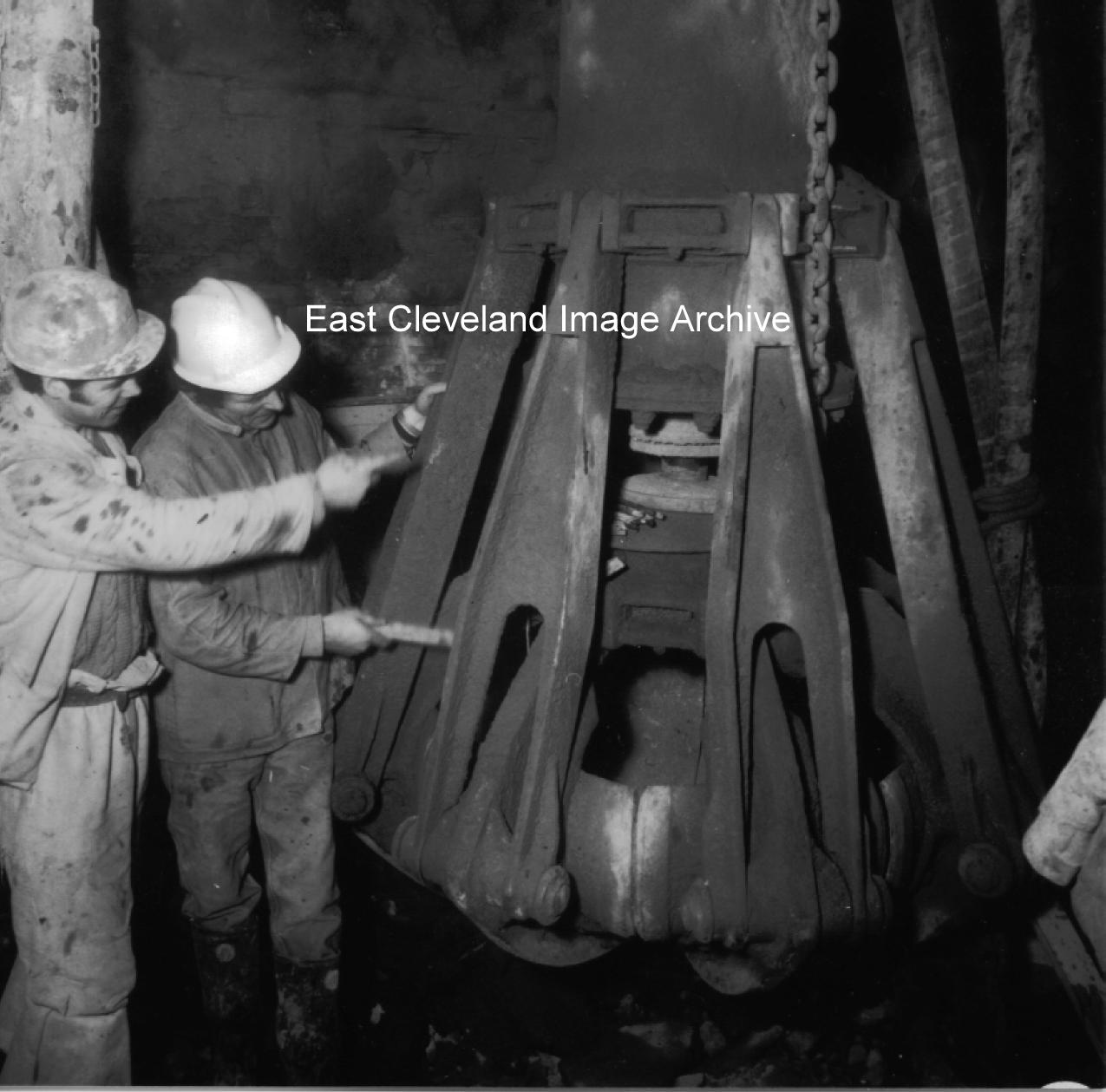

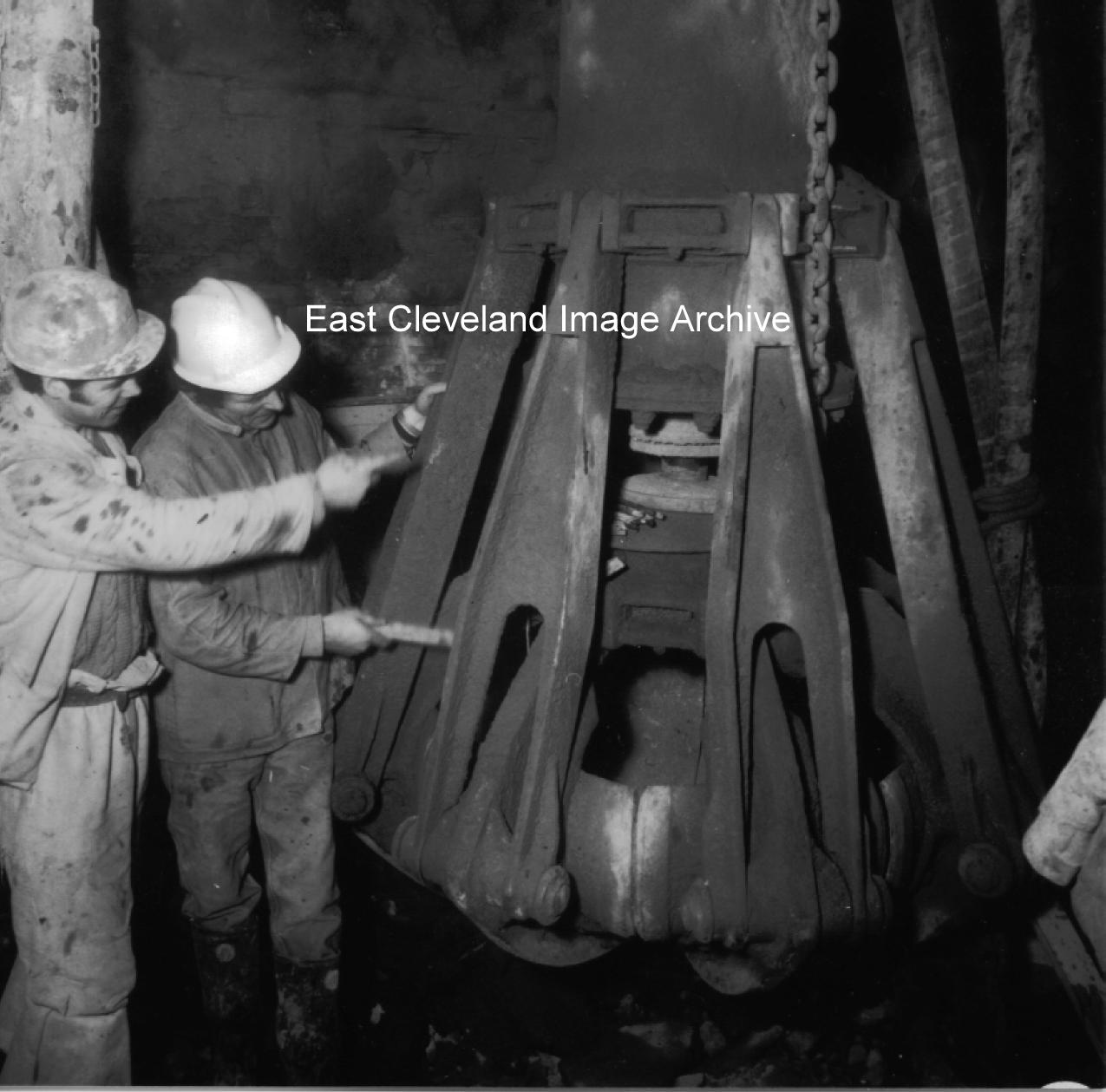

I couldn’t think of a better title myself! When you’re sinking a shaft, where does the muck go – to the bottom of course! – this fixes that problem. The grab was suspended under the staging in the shaft which in turn was suspended on steel ropes from the stage winder. The ”cactus grab” was powered with compressed air, operated by a man in a small cab – it worked magnificently. Alan Franks tells us:”This could be the shaft grab in the middle of Cragg Hall roundabout.”

Image and information courtesy of Alan Franks, also thanks to Alan for the update.

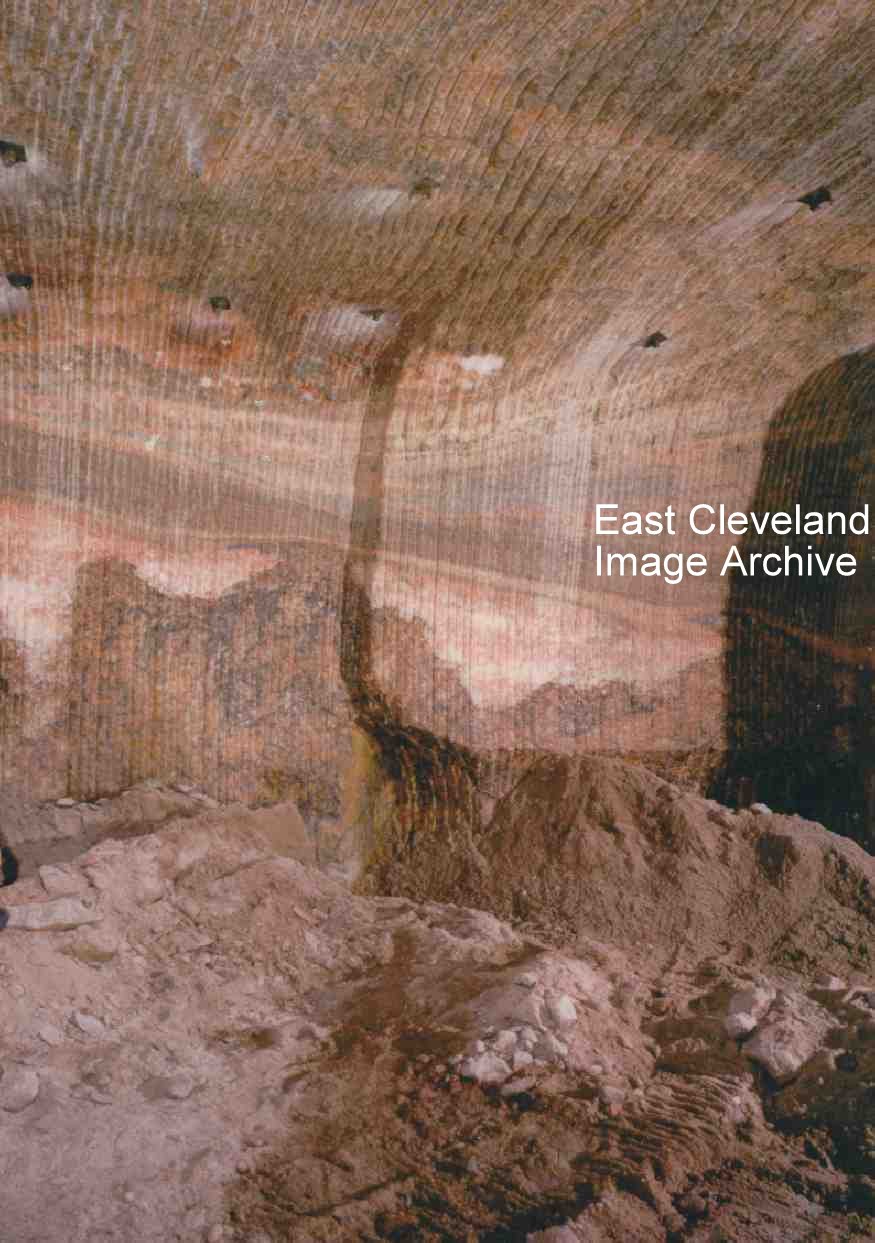

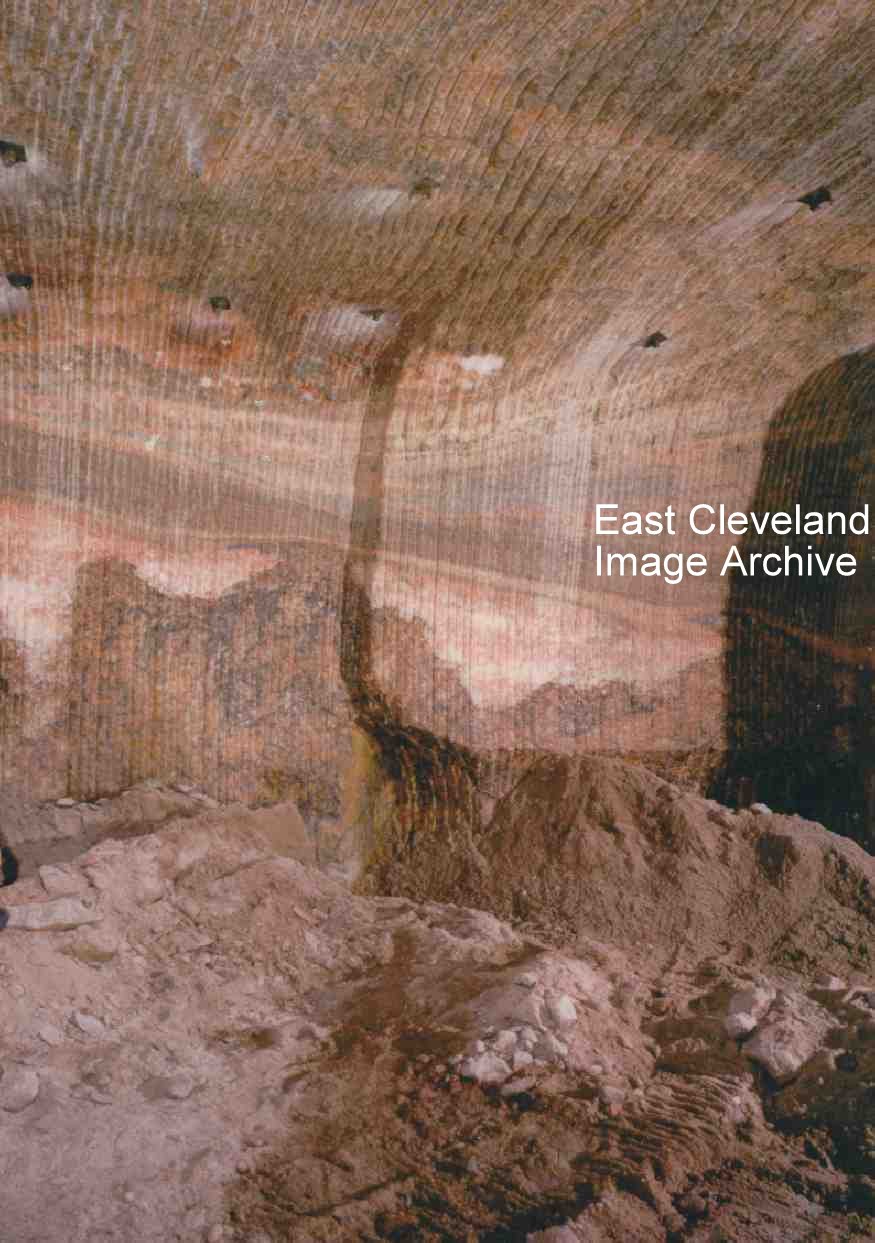

Because of the way the potash is won, the machinery leaves a nice clean edge on the tunnel walls – showing the geology off to its best advantage – also useful to tell you what you are cutting into as well!

Image courtesy of Alan Franks.

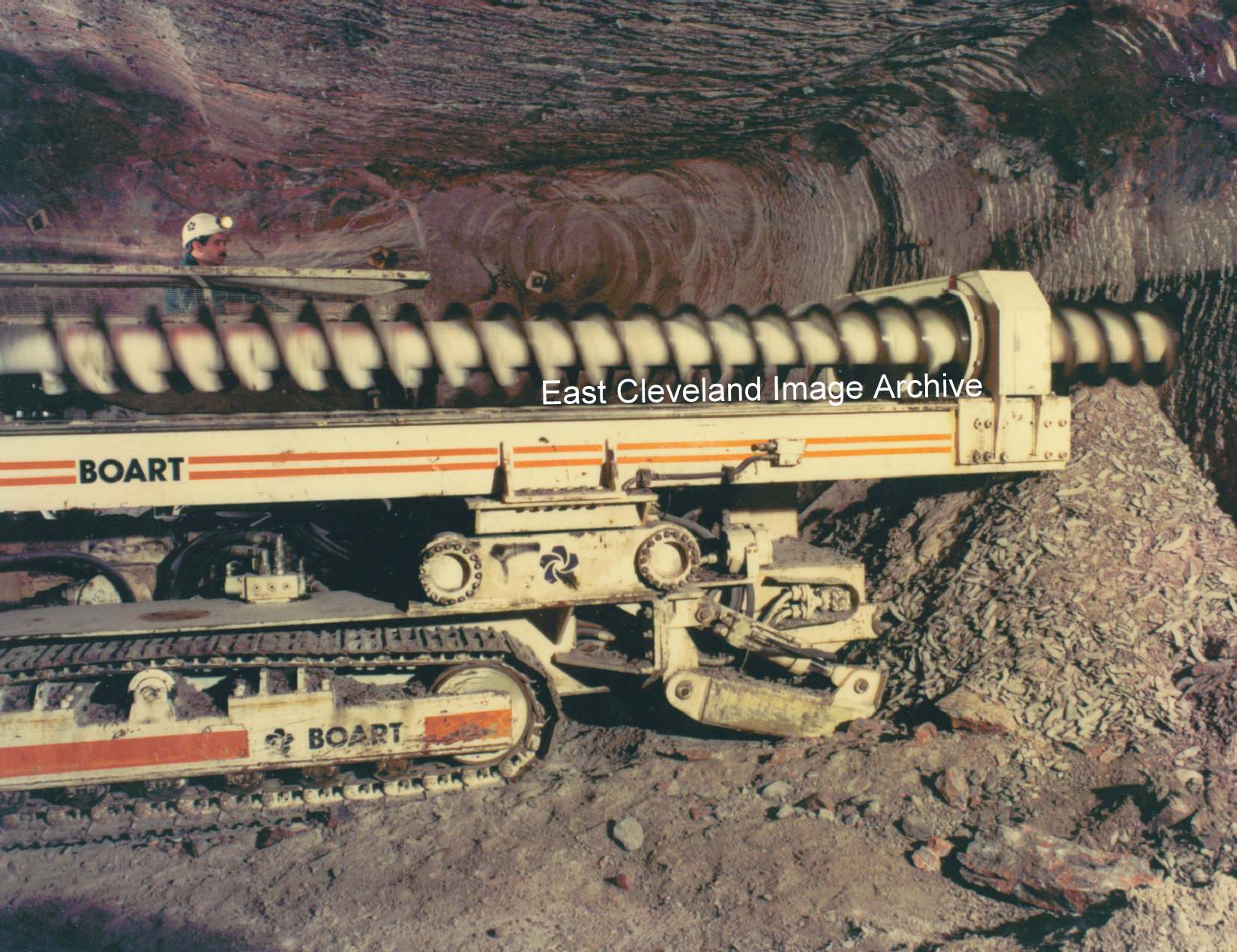

As if one wasn’t enough – but I believe they go as far as six boom – pretty awesome!

Image courtesy of Alan Franks.

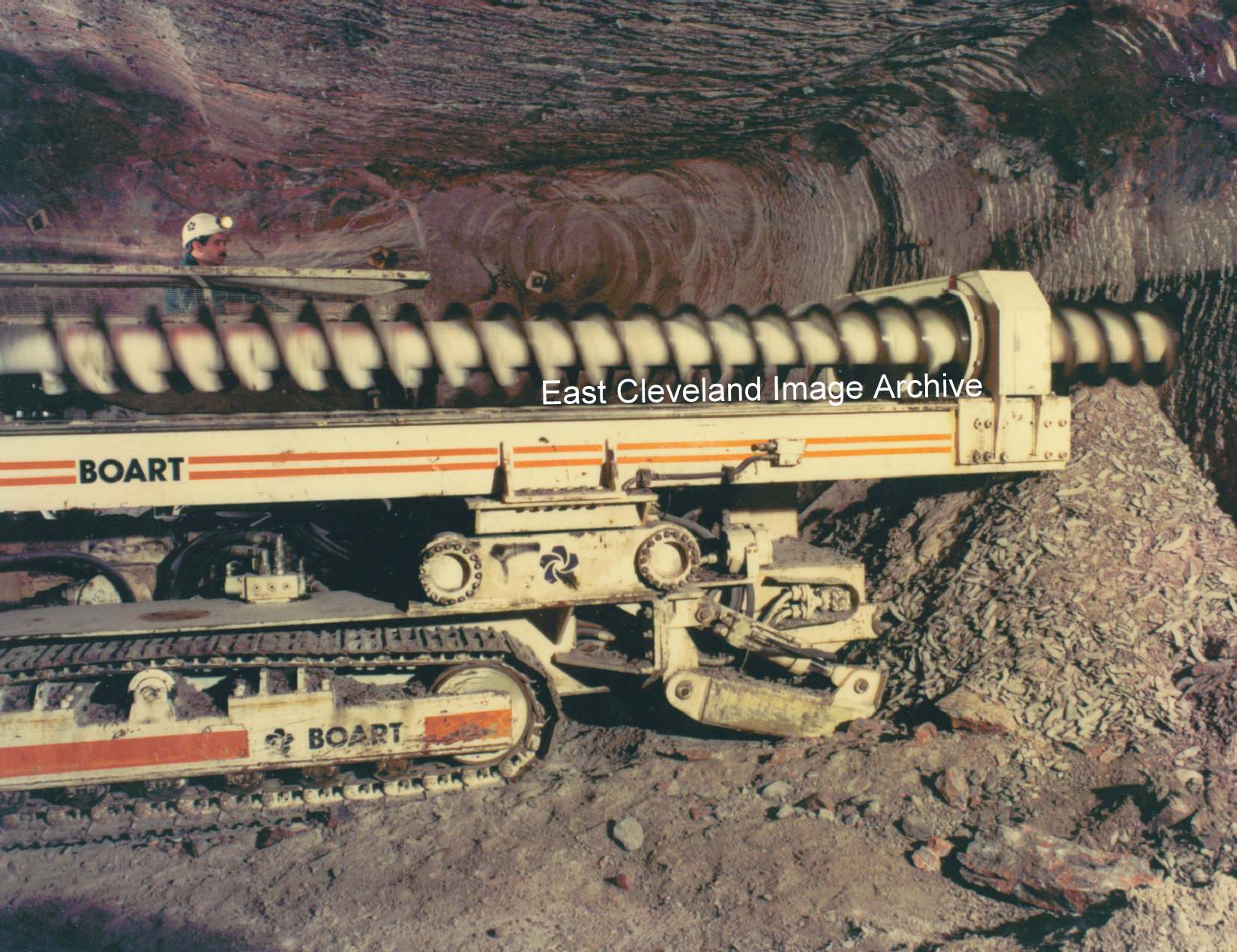

Heliminers aren’t the only exotic pieces of machinery in use below – here is an Auger Borer – pretty useful if you want to make a bang! Ian Benson tells us: ”The fitted the scroll borer to an old joy shuttle car chassis several of these were built in the underground workshops. They immediately were called Scud borers as the first Gulf war was underway at the time and named after Saddam Hussein’s ineffective Scud missiles. These borers were a little crude but they did the job apart from being a little unwieldy.”

Image courtesy of Alan Franks and thanks to Ian Benson for the update.

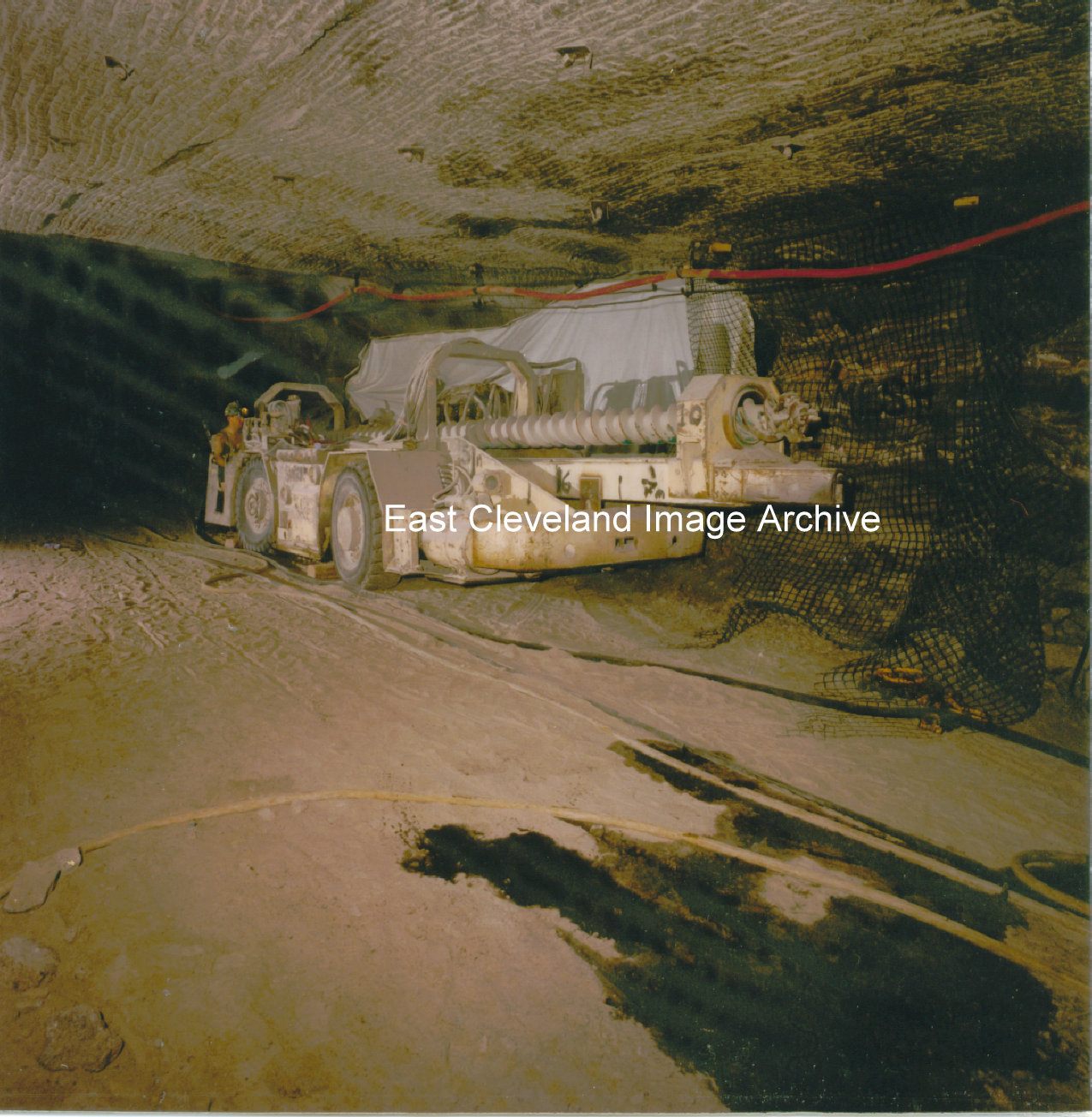

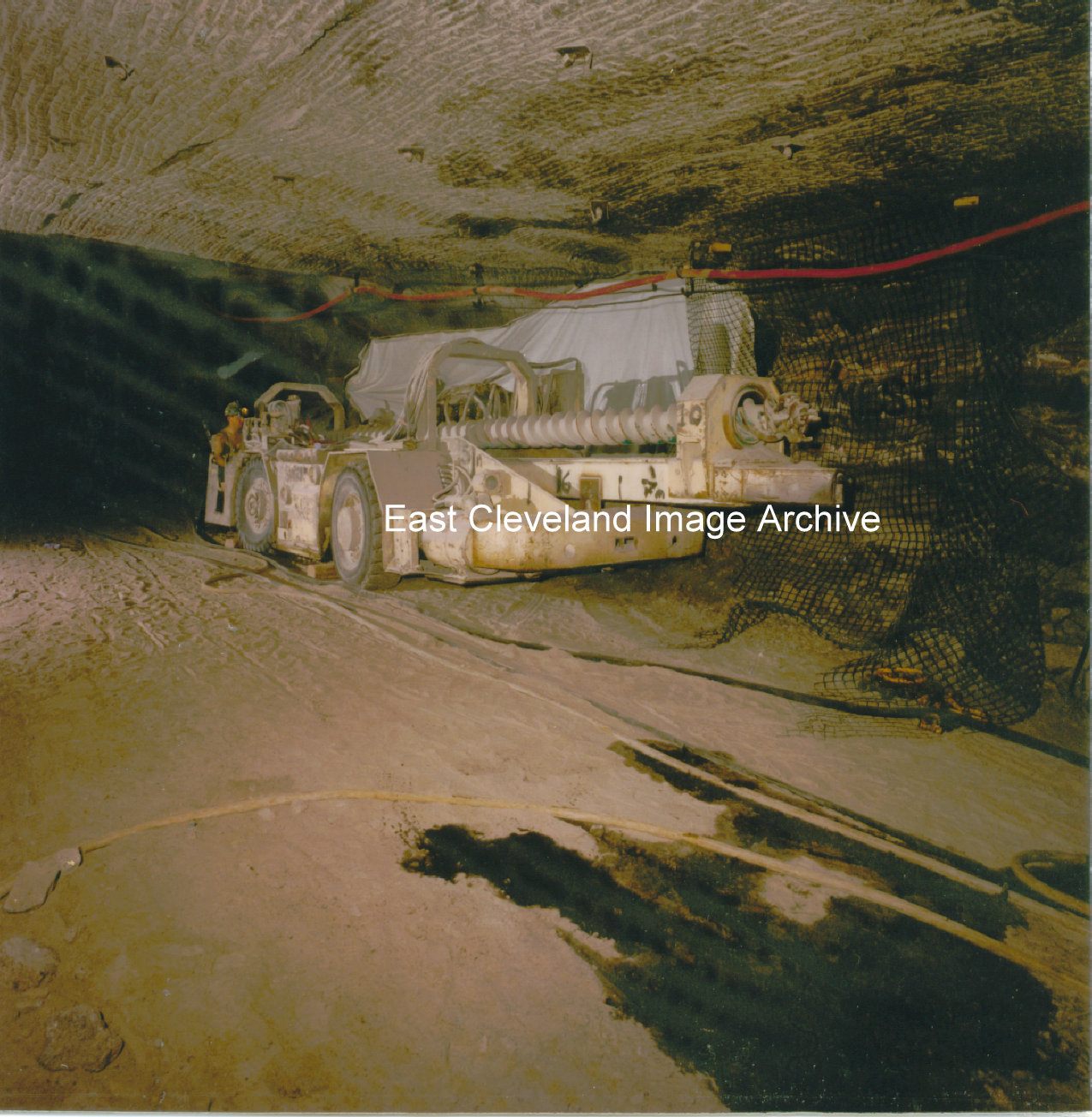

This is an image of a shuttle car collecting product from a Heliminer; the mined potash passing over the front of the Heliminer for collection in the cargo area.

Image courtesy of Alan Franks.

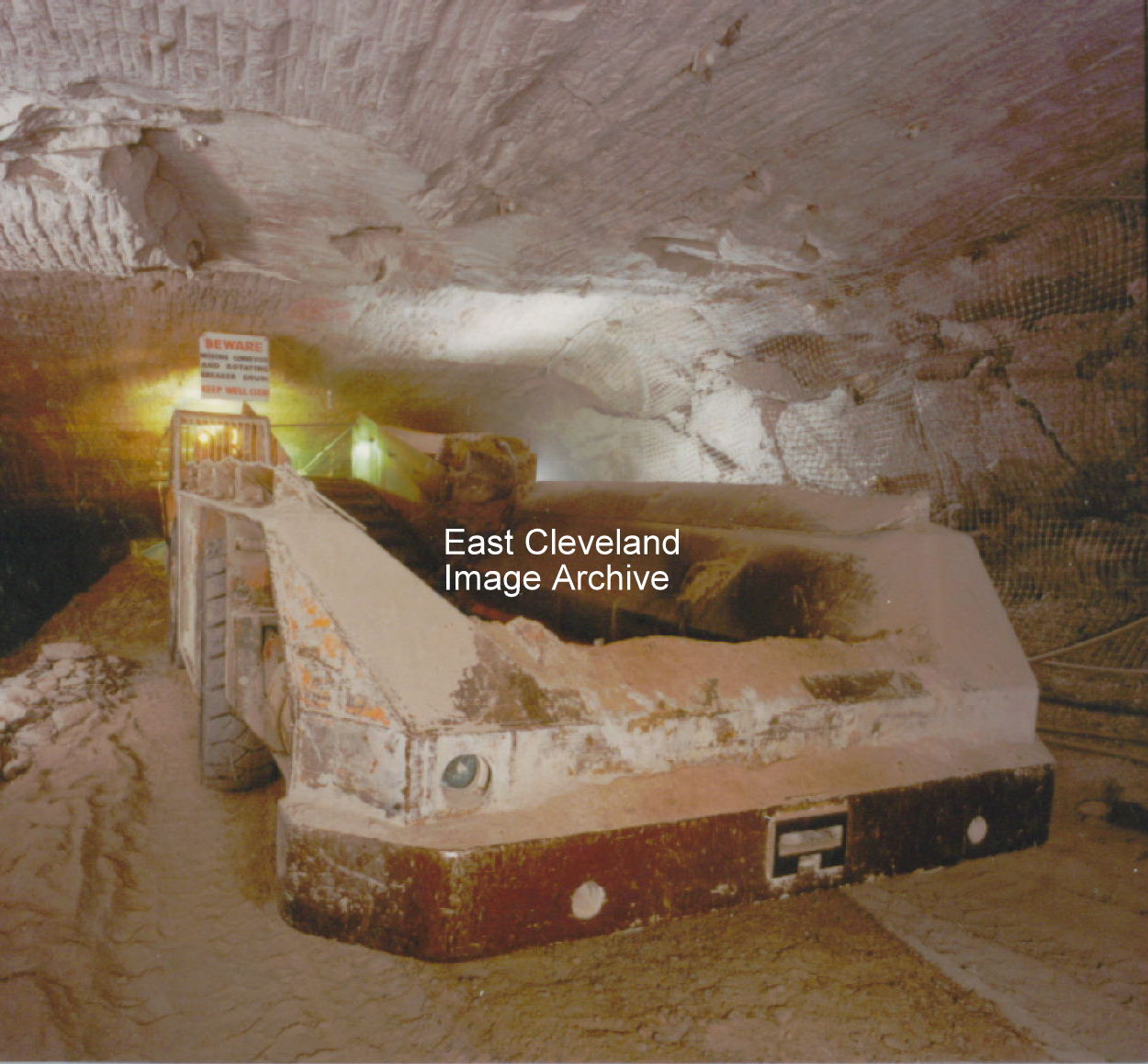

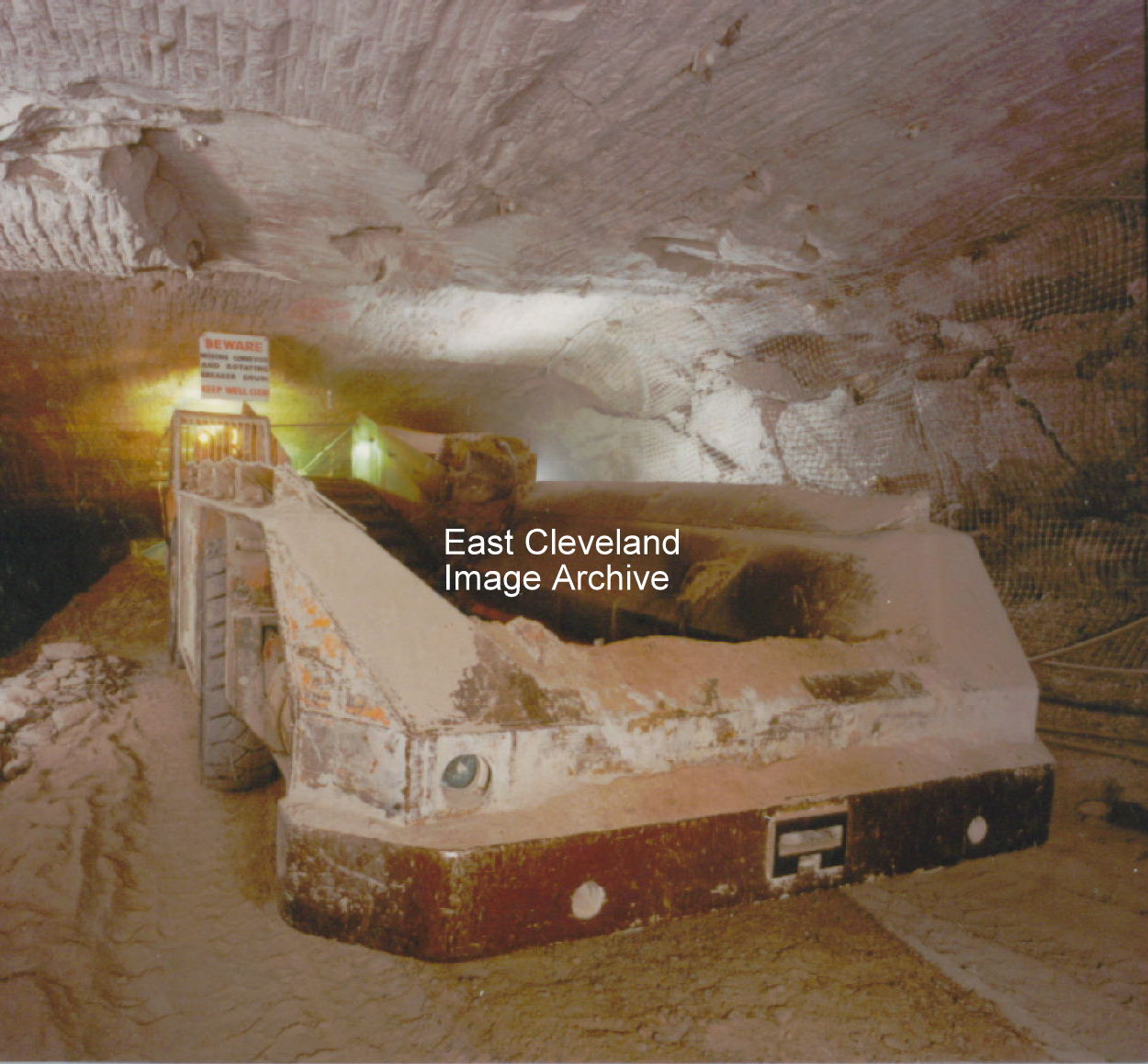

Looks kind of space age, but this is strictly utilitarian; designed to get product (potash) from the back of the miner onto a moving belt system.

Image courtesy of Alan Franks.

|

|

Recent Comments