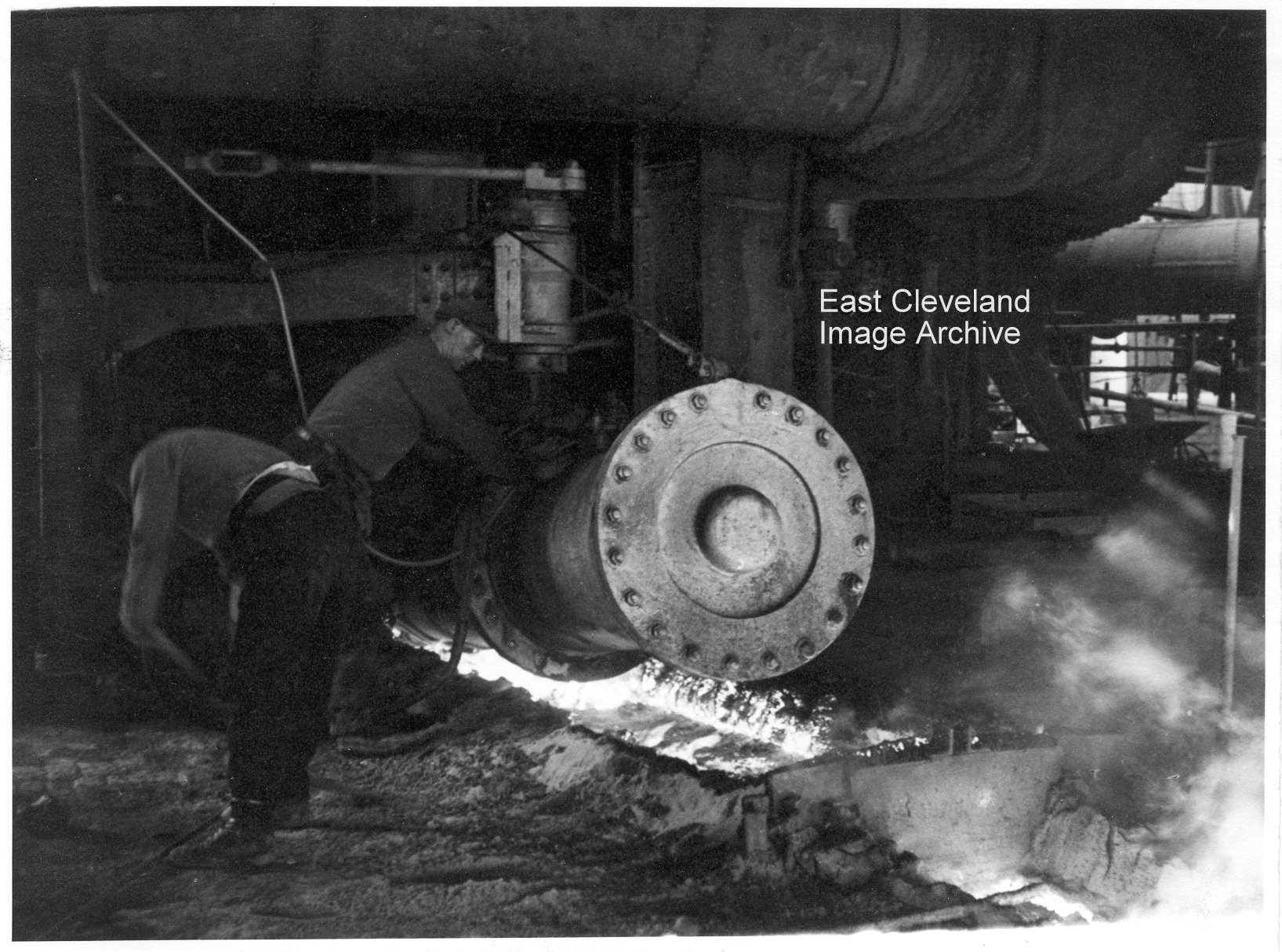

A very atmospheric shot of No. 5 blast furnace casting on Skinningrove; you can almost taste the sulphur! The ”gate” in the sand runner is to skim the slag off the iron and divert it towards the waiting slag ladles, the iron carries on straight ahead. The most dangerous time in the tapping process is when the liquid iron and slag are almost exhausted – because the system is under pressure the pressure seal can blow through the tap-hole sending slag and iron spraying in all directions, very pretty, but very dangerous!

The device which can be seen facing the camera is actually the “Clay gun”, a device for injecting clay into the taphole at the end of a cast, to stop the flow of iron. It looks like the Frontside lads are tidying up at the end of a cast. The large circular pipe above is the “Bustle main” which fed hot blast from the stoves into the furnace via the tuyeres which were spaced radially round the furnace. Latterly the Clay gun was powered by electricity, and it was the shift electricians duty to be there in case the gun failed to work, as things could get quite hairy if the gun failed to stop the taphole. The procedure was to start to bring the furnace “off blast” if the gun failed. In the meantime as a safety precaution the furnace would “Pull wind”.

Image courtesy of the Pem Holliday Collection.

Recent Comments