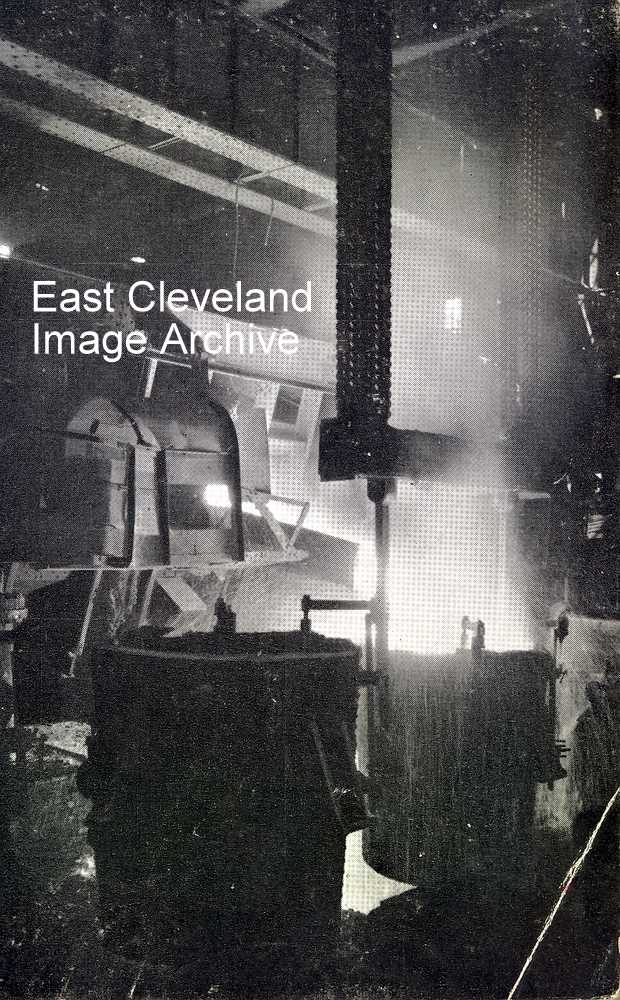

This image of A furnace first tap with number 1 (75 ton crane), before the main hoist chains were changed to wire ropes. After the 8 (or 12 for the ’Big’ furnaces) hour process of turning a charge of cold and hot metals into steel, the climax usually came quickly after a flurry of samples of steel and slag to the shift lab. The hooter would sound, the bangalore torpedo (more precisely ’the shaped charge’) would blow out the tap hole and the furnace would heel over to discharge it’s first potful of molten metal. Eric Johnson told us: “The scene always reminded me of what I thought Dante’s Inferno would look like – flames up to the rafters, (sometimes bringing a flurry of pigeons down), the furnace hand on the tapping stage hurling the alloying charges of coal, niobium, ferro-manganese etc. surrounded by smoke and light and heat. The furnace tilting further and further with each potful until it was spent. The pots in their turn travelling sedately to the Ingot Shed across the way and charging rake after rake of ingot moulds with the liquid metal. Sometimes a ’flying stopper’ made it more hazardous to empty the pots as it was then impossible to stop the flow of metal between moulds and everybody in the Ingot Shed would get a scorching (if they were unlucky they’d get a lot worse!) – and, as Bob says, a wet pot could create a shower of incandescent metal dancing around the pitside”. Stan Henderson tells us: ”Awesome! Better than any fireworks display I have seen.”

Thanks Eric Johnson and Stan Henderson for the updates.

Recent Comments